A precision fabric, webbing, zipper finishing machine and its control method

A finishing machine and fabric technology, applied in the field of dyeing machinery, can solve the problems of inability to meet the full automation process of chain belts and low efficiency of manual processing, and achieve the effect of ingenious design, high reliability, and avoiding secondary winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the implementation and protection of the present invention are not limited thereto. If there are no specific details below, those skilled in the art can refer to the prior art.

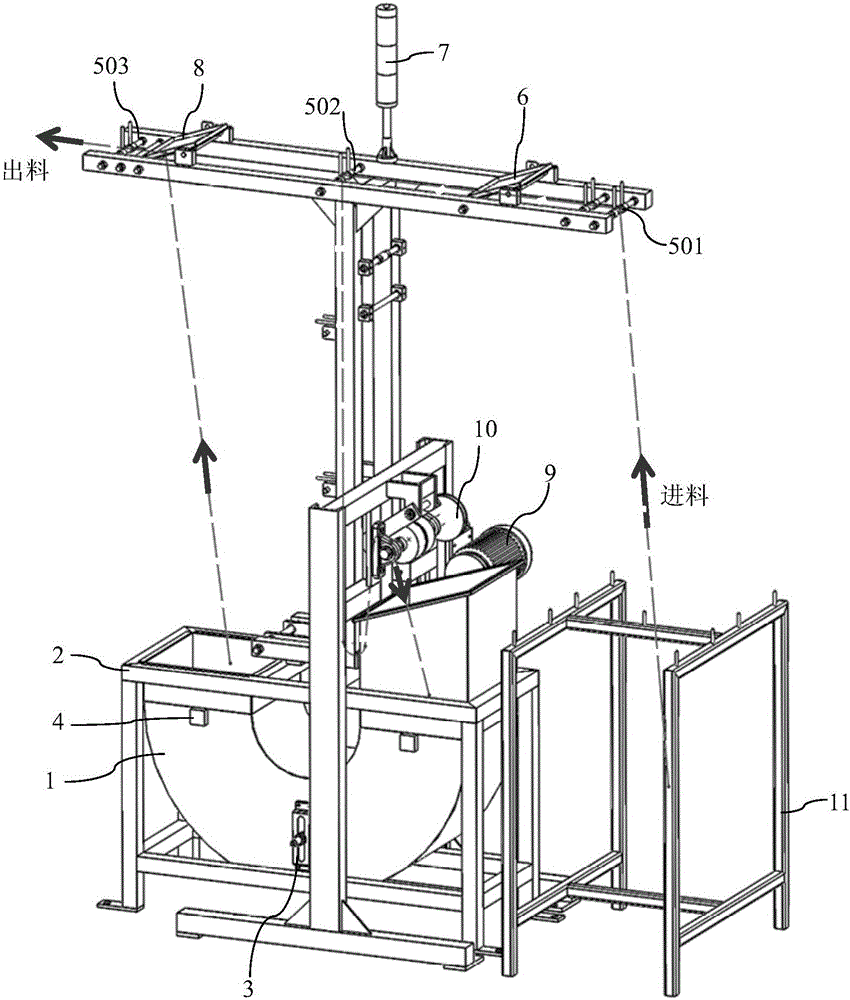

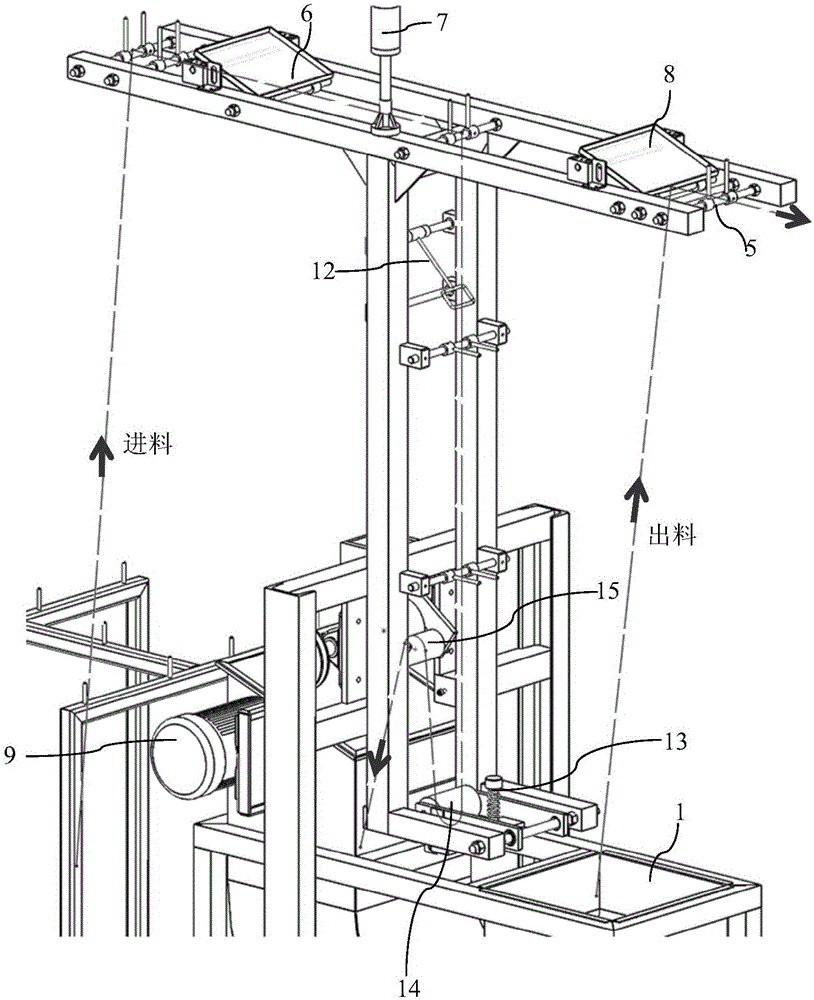

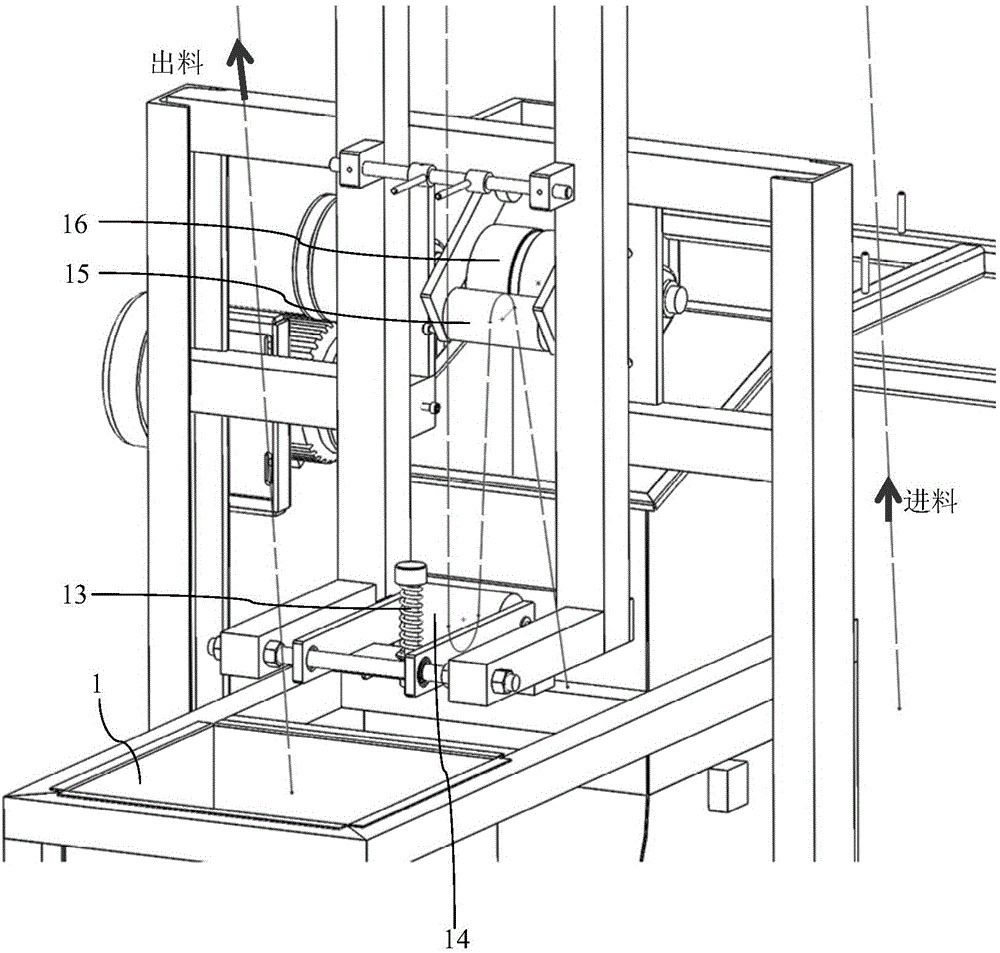

[0033] Such as Figure 1 ~ Figure 3 As shown, a finishing machine for precision fabrics, ribbons, and zippers in this example mainly includes cloth storage tanks, brackets, low-level sensors, high-level sensors, belt-in detection board components, belt-out detection board components, servo motors or frequency conversion control motors , broken belt detection component, tensile stress control component, driving roller and other components, the cloth storage tank 1 is fixedly installed on the bracket 2, and makes the two openings of the cloth tank vertically upward; the cloth storage tank 1 is U-shaped, composed of two straight lines The cavity is connected with a semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com