Assembling machine table capable of tightening automobile hub bolts with variable diameters and at variable positions

An automobile wheel hub and displacement technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of large equipment investment, reduce labor costs, improve product quality, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

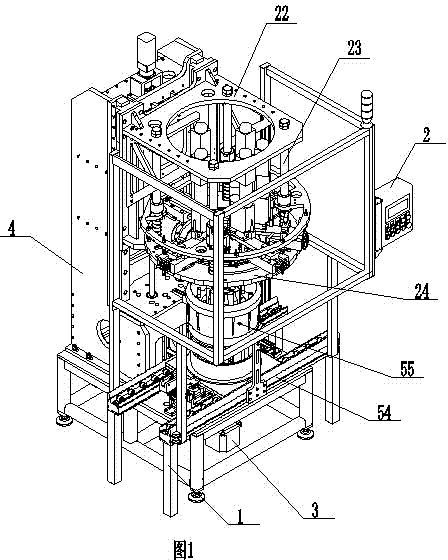

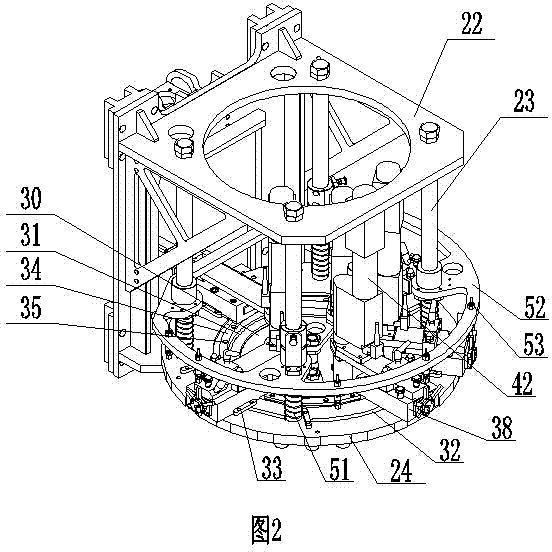

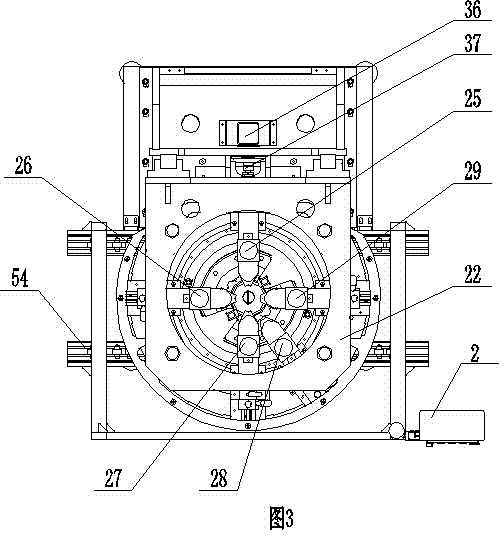

[0024] The assembly machine for tightening automobile hub bolts with variable diameter and displacement includes a frame 1, a program control box 2, a lifting and locking device 3 and a variable diameter and phase-changing tightening device. A support plate 4 is fixedly installed on the frame 1, and a lifting locking device 3 is installed on the frame 1 below the front end of the support plate 4.

[0025] The lifting and locking device 3 is composed of a rotating motor 5, a reducer 6, a coupling 7, a transmission shaft 8, a mounting plate 9, a jacking cylinder 10, a locking cylinder 11, a transmission shaft box 12 and a workpiece lifting and placing plate 13; A transmission shaft box 12 is installed on the rotating electrical machine 5 through a reducer 6; a transmission shaft 8 is installed in the transmission shaft box 12 through a bearing 14, and the output shaft of the reducer 6 extends into the transmission shaft box 12 and is connected to the transmission shaft through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com