Submerged arc welding processing method of curtain wall buried element

A technology of submerged arc welding and processing method, applied in welding accessories, welding equipment, welding equipment and other directions, can solve the problems of non-pressure submerged arc welding machine, the welding of curtain wall embedded parts with high mechanical strength of embedded parts, etc., to achieve welding efficiency High quality, guaranteed quality, and cheap flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

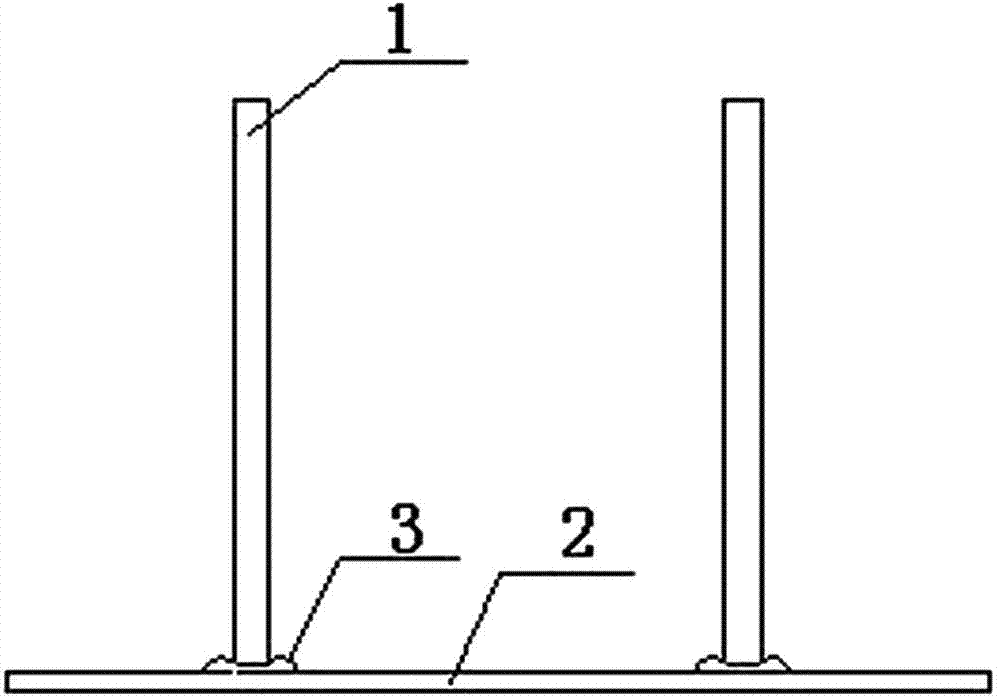

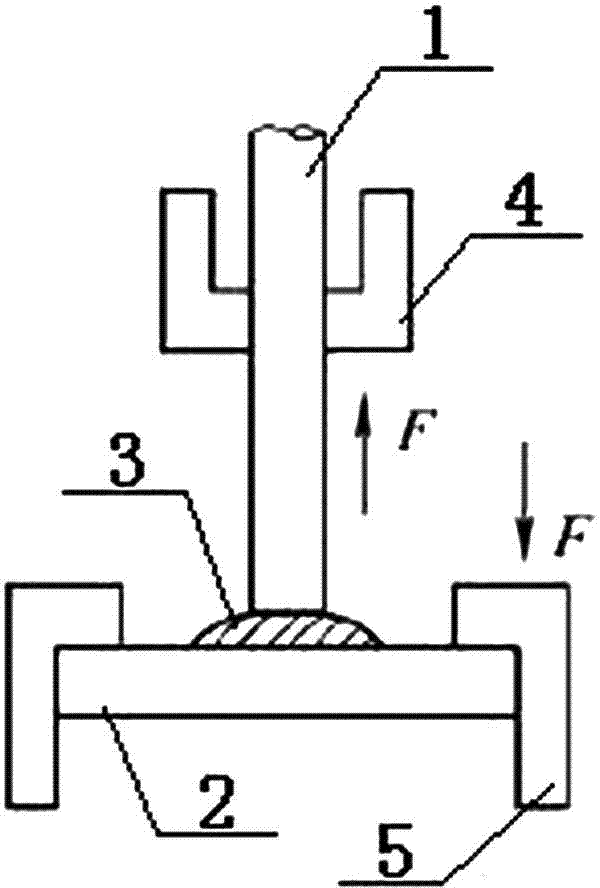

[0027] Now, the present invention will be described in further detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the components related to the present invention, and should not be construed as limiting the present invention.

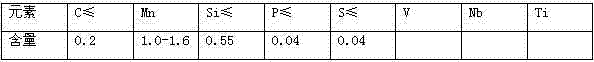

[0028] Such as Figure 1-2 As shown, the submerged arc welding processing method of curtain wall embedded parts of the present invention comprises the following steps:

[0029] (1) Make welding tooling: change the bench drill into welding tooling, specifically - remove the motor and transmission mechanism of the bench drill, and wrap the handwheel of the bench drill with insulating tape or insulating hose to completely insulate the handwheel from the outside world. Pad an insulating formwork at the bottom of the bench drill to avoid electromagnetic induction when the bench dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com