Frame type rubber diaphragm press filter

A technology of rubber diaphragm and filter press, which is used in filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems that the filter chamber volume is not very large, the polypropylene diaphragm is not elastic, and the cost is high, and the material and structure can be achieved. Reasonable, good sealing performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

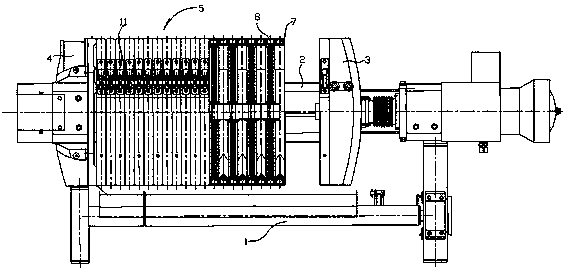

[0054] Figure 1~Figure 17 Among them, the box-type rubber diaphragm filter press has a frame 1, and the frame has a main beam 2 in the longitudinal direction. On the frame, one end of the main beam has a hydraulically driven pressing plate 3, and on the frame, the other end of the main beam There is a thrust plate 4 at one end, and a filter press device 5 on the main beam. The filter press device is a plurality of sets of filter press units 6 connected in sequence.

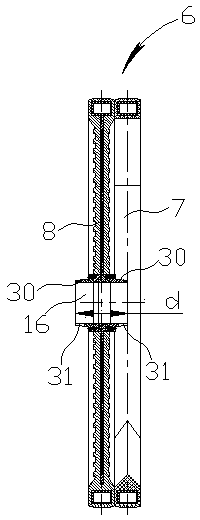

[0055] The filter press unit has a connected filter frame 7 and a box-type diaphragm filter plate 8,

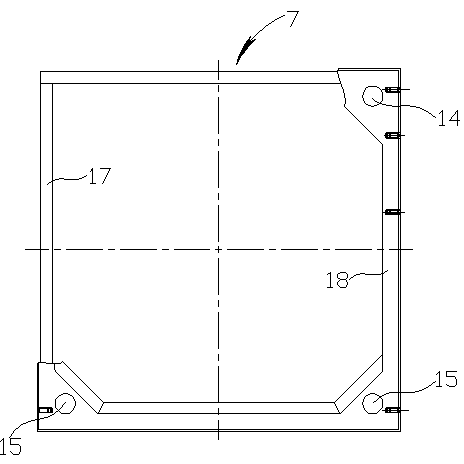

[0056] The filter frame is a rectangular frame, the box-type filter plate is a rectangular flat plate, the left and right sides of the box-type filter plate rectangular plate have grooves 9 and 10 respectively, and the two sides of the box-type filter plate and filter frame have support The handle 11 supported on the main beam, the groove bottom of the box-type filter plate are evenly distributed with protrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com