Rack for a rack-and-pinion steering system of a motor vehicle

A rack type, steering gear technology, applied in the direction of mechanical steering gear, steering gear, steering mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

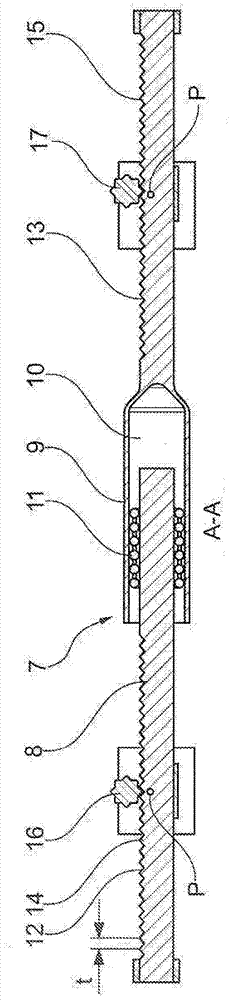

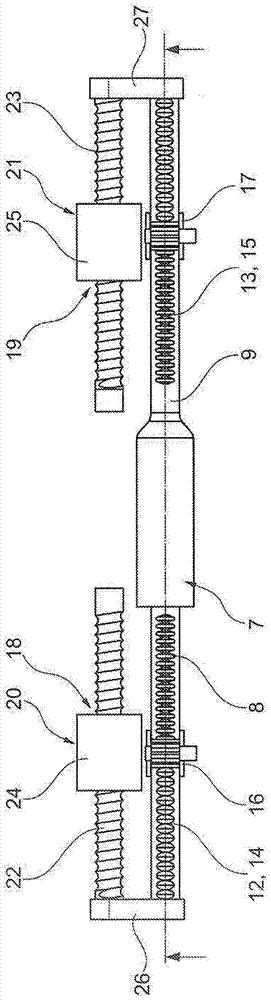

[0032] In order to understand the present invention better, at first combine self known rack type steering gear (as Figure 6 and Figure 7 Schematically shown like that) illustrates the problem that the rack 1 is connected at its axial ends to the tie rod 3 via a tie rod hinge 2 , and the tie rods are connected at their ends facing away from each other via a steering arm hinge 4 is connected to a steering arm 5 which acts on a not further shown wheel carrier in order to steer the steering wheel 6 . From Figure 6 It can be seen that the axes of action of these steering arms 5 intersect each other at a point of intersection M which lies on the axis of rotation of the non-steered rear wheels of the vehicle. In this view, the point of intersection M is shown displaced. Such a configuration of the steering arm 5 can be the main prerequisite for fulfilling the so-called Ackermann condition as described at the outset.

[0033] At the neutral position of the rack steering gear (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com