GOA circuit repairing method

A repair method and circuit technology, applied to static indicators, instruments, etc., can solve problems such as damage, relatively high manufacturing process, and requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

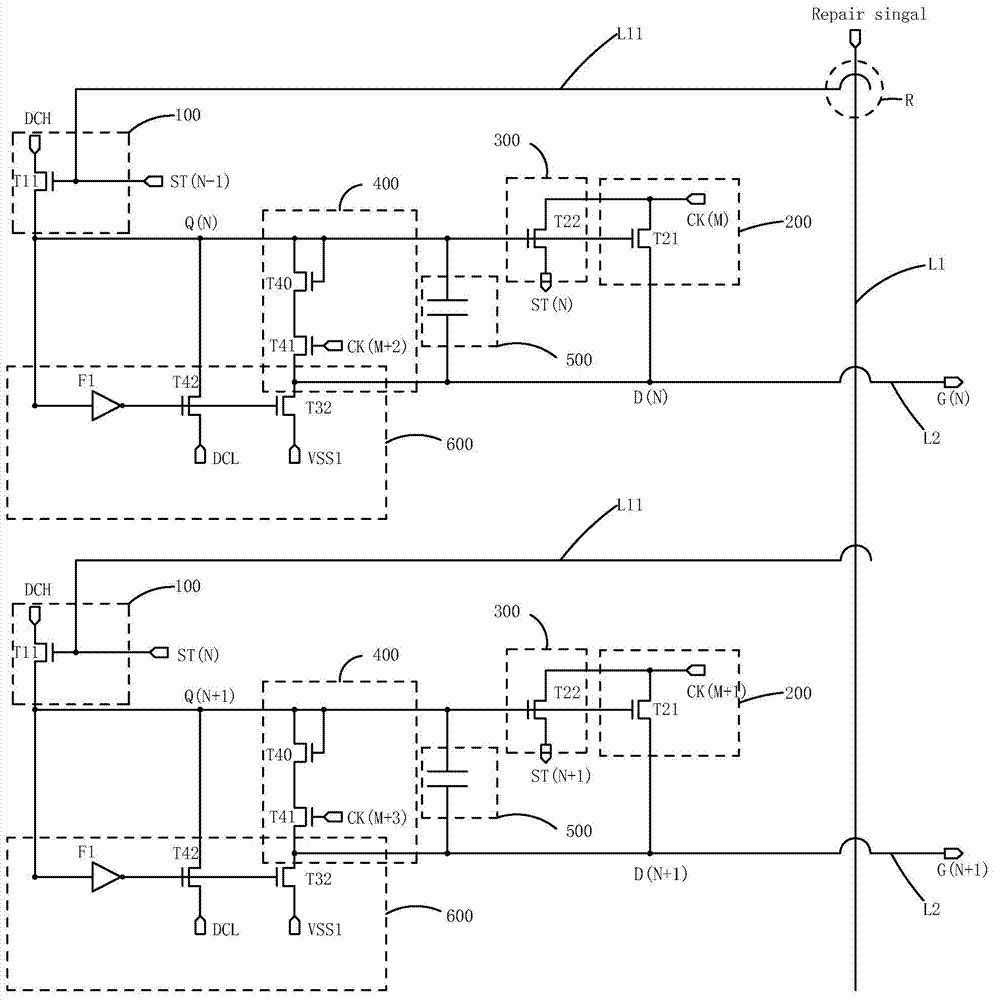

[0064] First, a plurality of cascaded GOA unit circuits, a repair signal Repair signal, and a repair signal line L1 electrically connected to the repair signal Repair signal are provided;

[0065] Wherein, each level of GOA unit circuit includes a pull-up control module 100, a pull-up module 200, a downlink module 300, a first pull-down module 400, a bootstrap capacitor 500, and a pull-down maintenance module 600;

[0066]Assuming that N is a positive integer, in the Nth-level GOA unit circuit, the pull-up control module 100 includes an eleventh thin film transistor T11, and the gate of the eleventh thin film transistor T11 receives For the scanning control signal ST(N-1) of the GOA unit circuit, the source is electrically connected to the constant voltage high potential DCH, and the drain is electrically connected to the first node Q(N); the downlink module 300 outputs the Nth + the scanning control signal ST(N) of the GOA unit circuit of level 1; the pull-up module 200 outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com