Cement calciner control method and system based on combined model predictive control technology

A cement calcining furnace and combined model technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of single control variable and inability to adapt to the strong coupling between multiple variables, achieve good tracking performance, overcome the Influence of time delay factors and the effect of simple identification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

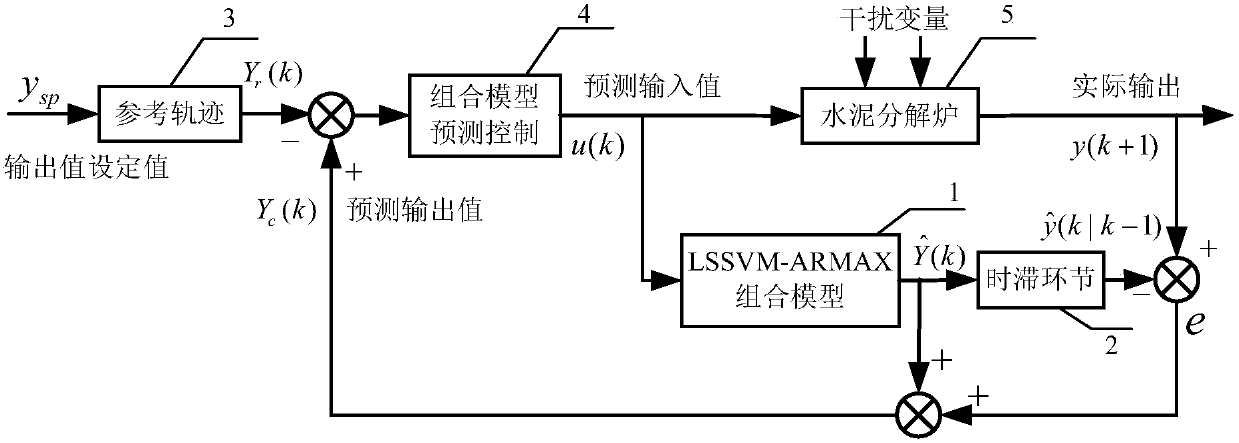

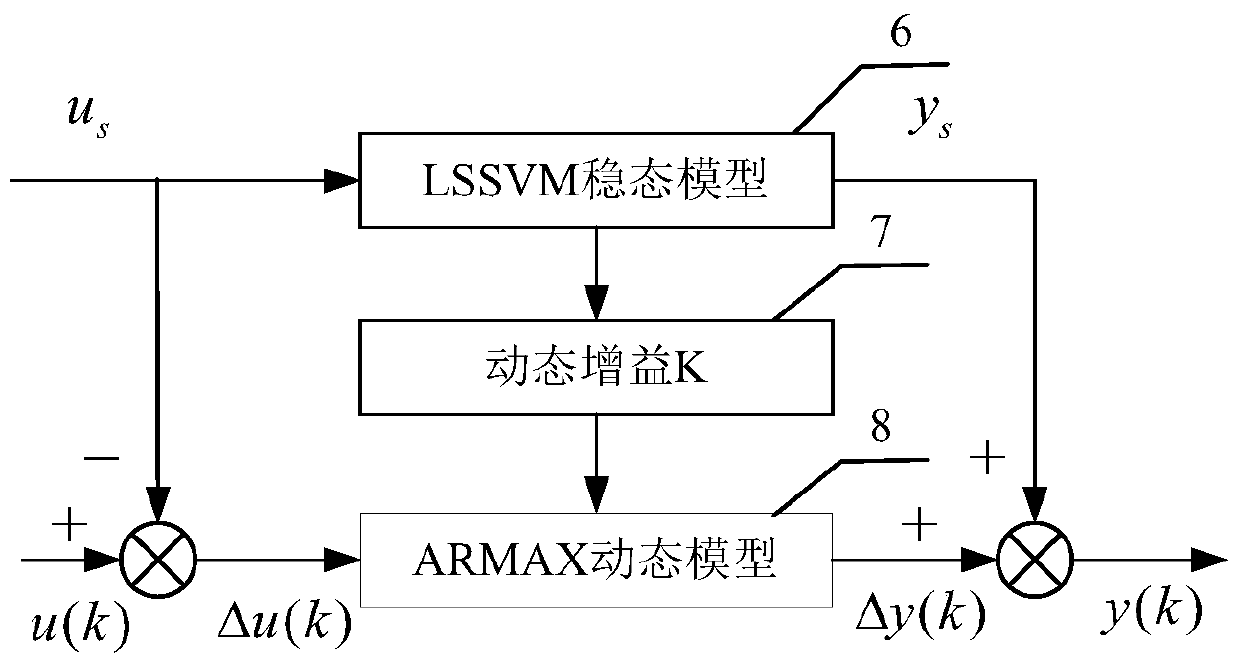

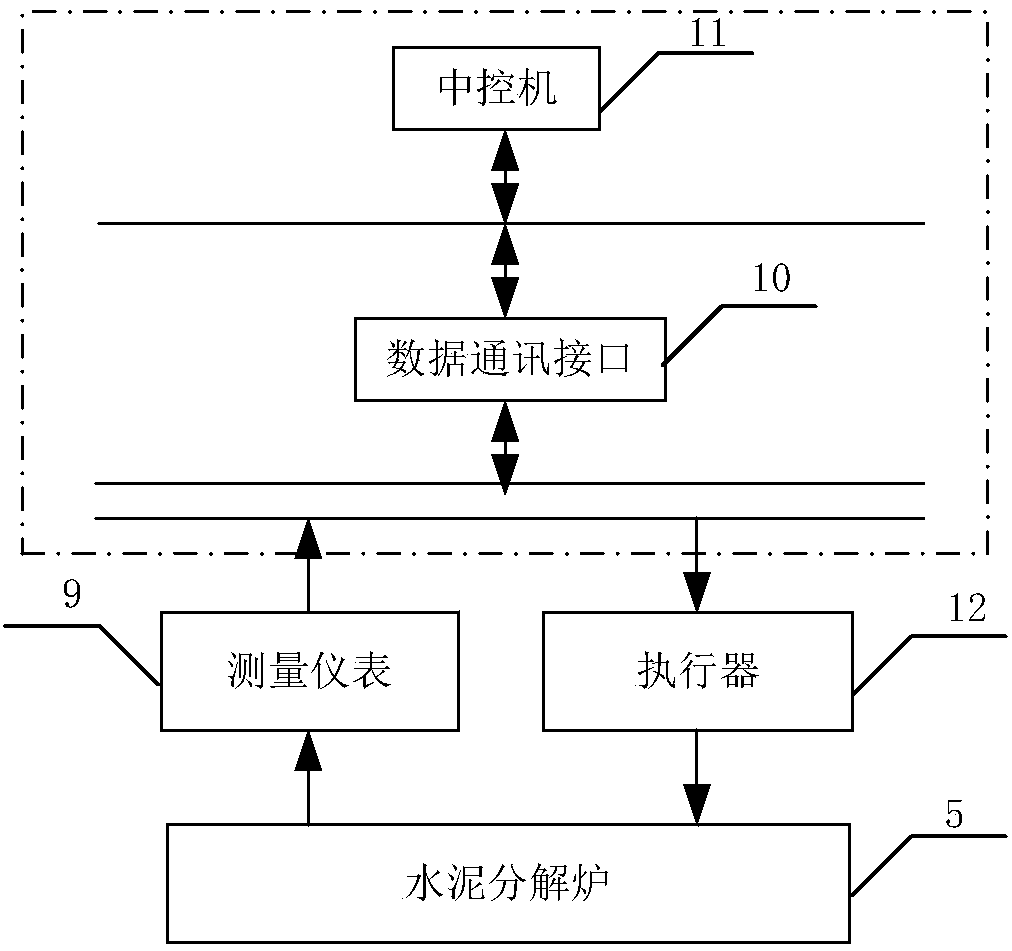

[0034] from figure 1 The flow chart and the flow chart of the cement calciner control method based on the combined model predictive control technology shown image 3 As can be seen from the block diagram of the cement calciner control system based on the combined model predictive control technology, a kind of cement calciner control method based on the combined model predictive control technology of the present invention comprises the following steps:

[0035] Step 1 Control variable selection

[0036]The coal feed rate of the calciner, the speed of the high-temperature fan and the opening of the baffle of the tertiary air duct are the main input control variables affecting the cement calciner system. They are the main sources of heat and gas in the calciner; Content and carbon monoxide content in the primary cylinder are the main output control variables a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com