An easily disassembled impeller flow sensor

A flow sensor and impeller-type technology, which is applied in the direction of volume/mass flow generated by mechanical effects, and through the detection of dynamic effects of fluid flow, etc., can solve the problem of inconvenient disassembly of impeller-type magnetic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

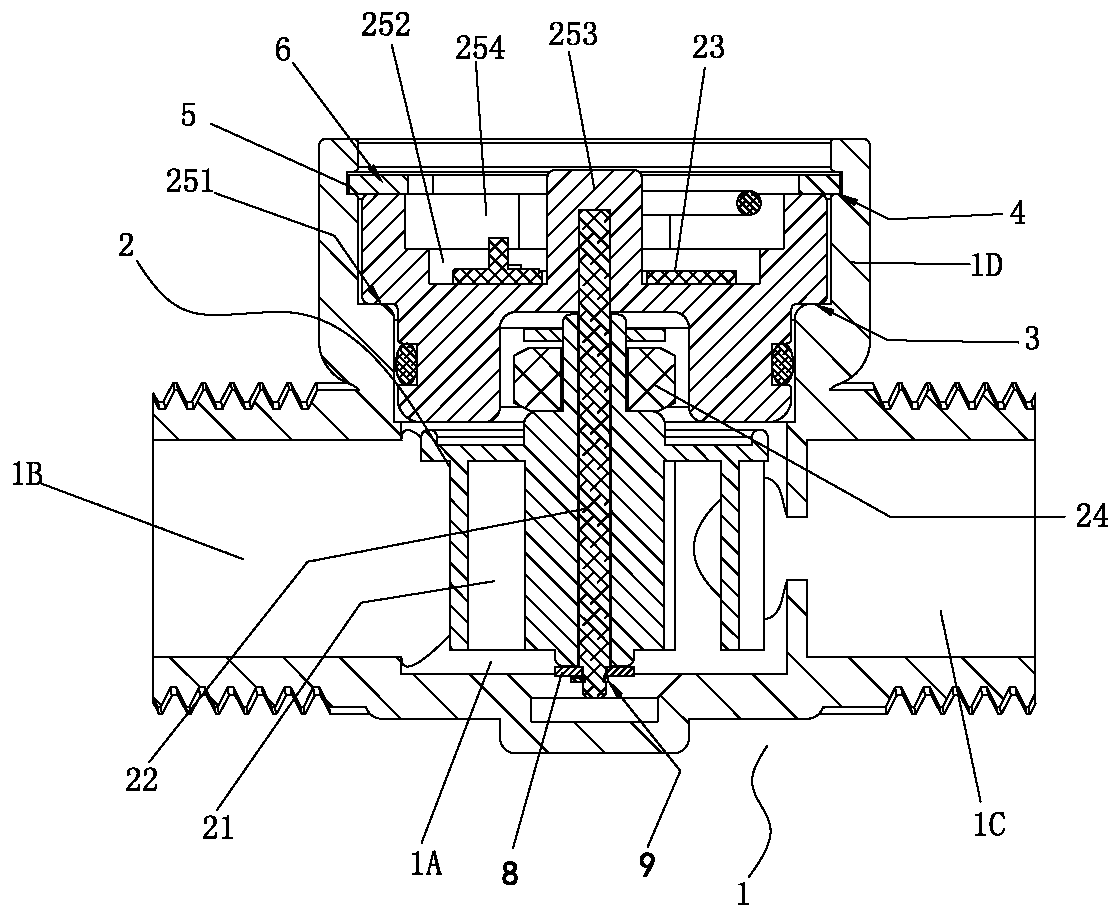

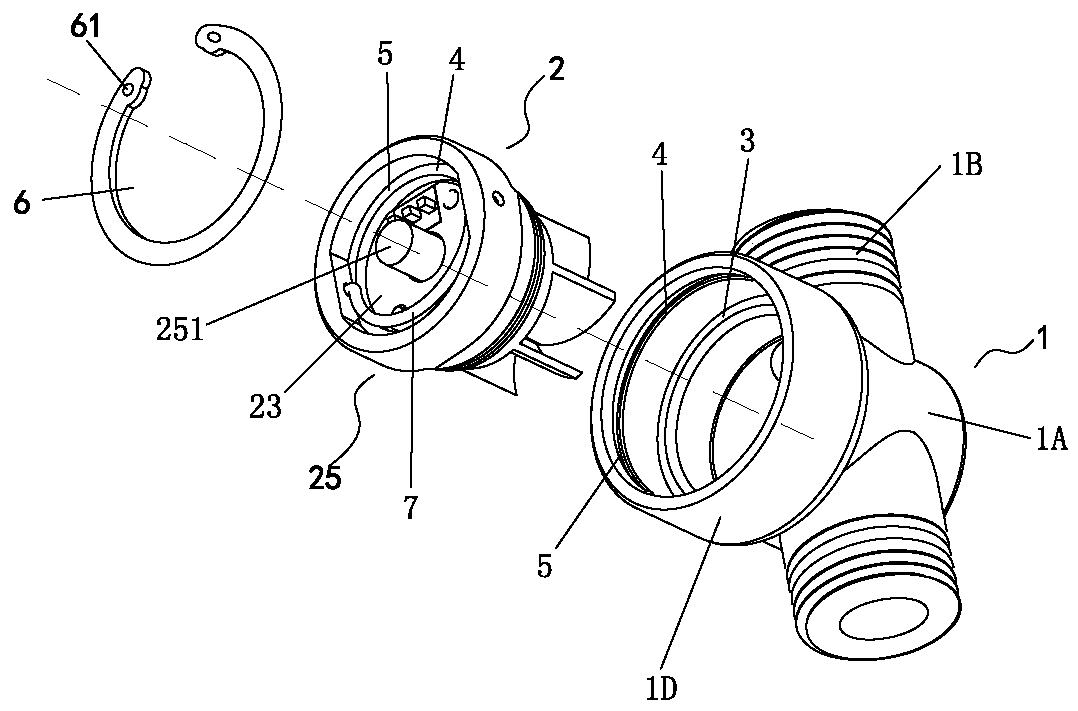

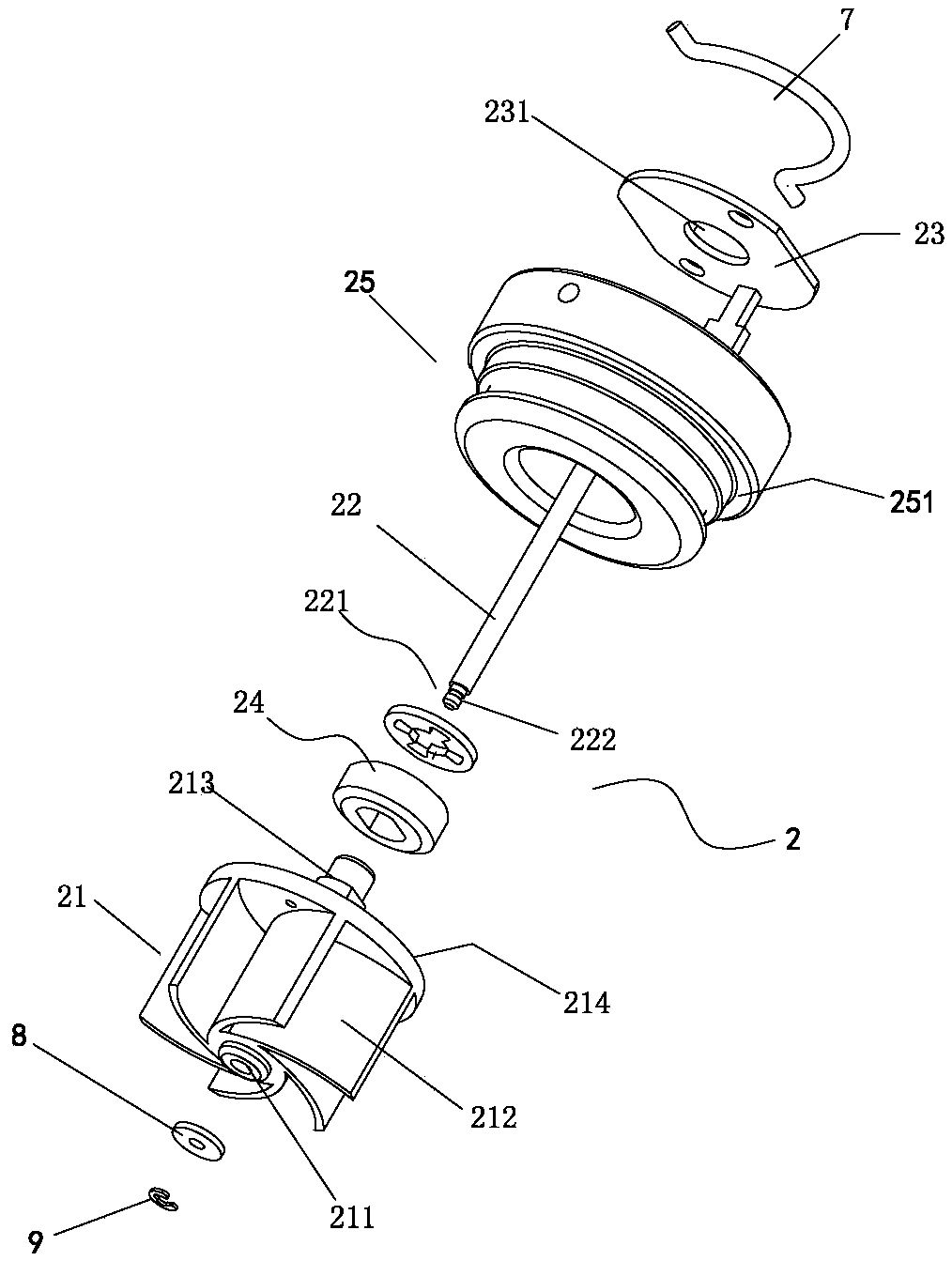

[0027] Such as figure 1 As shown, a detachable impeller-type flow sensor includes a housing 1 and an impeller-type sensor assembly 2. The housing 1 includes an impeller chamber 1A, a water inlet port 1B communicating with the impeller chamber, and a water inlet port 1B communicating with the impeller chamber. The water outlet interface 1C and the assembly seat 1D communicating with the impeller cavity, the impeller sensor assembly 2 includes the impeller 21, the impeller shaft 22, the circuit board 23, the Hall sensor (not marked in the figure), the magnetic assembly 24 and the base 25 ; The base 25 is detachably connected to the component seat 1D.

[0028] There is an inner ring platform 3 and an upper ring platform 4 inside the component seat 1D, and there is an annular clamping groove 5 on the wall of the component seat 1D at the upper surface of the upper ring pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com