Method for separation and purification of thermo-sensitive hydroxybutyl chitosan by phase transformation

A temperature-sensitive hydroxybutyl chitosan separation and purification technology is applied in the field of separation and purification of temperature-sensitive hydroxybutyl chitosan, which can solve the problems of limitation and no purification of temperature-sensitive hydroxybutyl chitosan, etc. To achieve the effect of increasing the molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

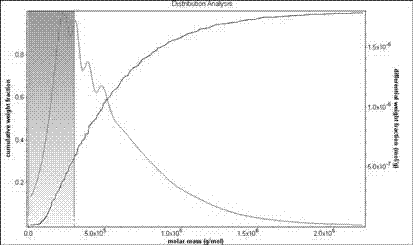

[0026] Concentrations of 2%, 10% and 20% sodium chloride aqueous solution and 2% thermosensitive hydroxybutyl chitosan aqueous solution were prepared respectively. First add 2% aqueous sodium chloride solution to 500ml of thermosensitive hydroxybutyl chitosan aqueous solution in a stirring state until white precipitates are separated out. After filtering the solution, add 500ml of 10% aqueous sodium chloride solution and stir fully. After the solution was filtered off, 500 ml of 20% sodium chloride aqueous solution was added, stirred thoroughly, and after the solution was filtered off, a white precipitate crude product was obtained.

[0027] The precipitate was washed with 70%, 80%, 90% and 100% acetone 500ml to desalt in turn, and finally a white precipitate was obtained. After the precipitate was vacuum-dried at 40°C, the refined pure product of temperature-sensitive hydroxybutyl chitosan was obtained. 7.4g.

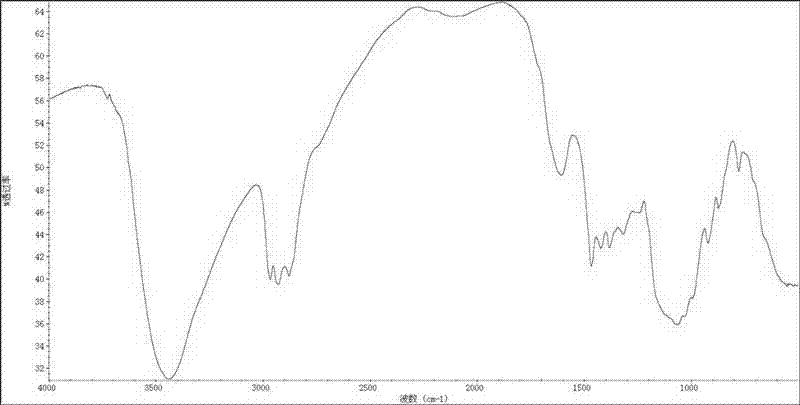

[0028]

Embodiment 2

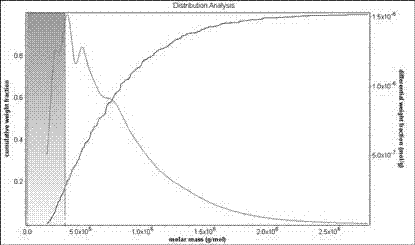

[0030] The concentrations were 4%, 15% and 20% sodium chloride aqueous solution, and 1% thermosensitive hydroxybutyl chitosan aqueous solution. First add 4% aqueous sodium chloride solution to 500ml of thermosensitive hydroxybutyl chitosan aqueous solution in a stirring state until white precipitates are separated out. After filtering the solution, add 500ml of 15% aqueous sodium chloride solution and stir fully. After the solution was filtered off, 500 ml of 20% sodium chloride aqueous solution was added, stirred thoroughly, and after the solution was filtered off, a white precipitate crude product was obtained.

[0031] The precipitate was washed with 70%, 80%, 90% and 100% acetone 500ml to desalt in turn, and finally a white precipitate was obtained. After the precipitate was vacuum-dried at 40°C, the refined pure product of temperature-sensitive hydroxybutyl chitosan was obtained. 3.2g.

[0032]

Embodiment 3

[0034] The concentrations were 5%, 15% and 25% sodium chloride aqueous solution and 0.5% thermosensitive hydroxybutyl chitosan aqueous solution respectively. First add 5% aqueous sodium chloride solution to 500ml of thermosensitive hydroxybutyl chitosan aqueous solution in a stirring state until white precipitates are separated out. After filtering the solution, add 500ml of 15% aqueous sodium chloride solution and stir fully. After filtering off the solution, add 500ml of 25% sodium chloride aqueous solution, stir well, and after filtering off the solution, a white precipitate crude product is obtained.

[0035] The precipitate was washed with 500ml of 70%, 80%, 90% and 100% ethanol in order to remove salt, and finally a white precipitate was obtained. The precipitate was vacuum-dried at 40°C to obtain the refined pure product of temperature-sensitive hydroxybutyl chitosan 1.6 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com