Betel nut packaging bag opening device

A packaging bag and betel nut technology, applied in the field of bag opening equipment, can solve the problems of high labor intensity, many workers, and low packaging efficiency, and achieve the effect of simple and reliable scheme, reduced labor intensity, and high opening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

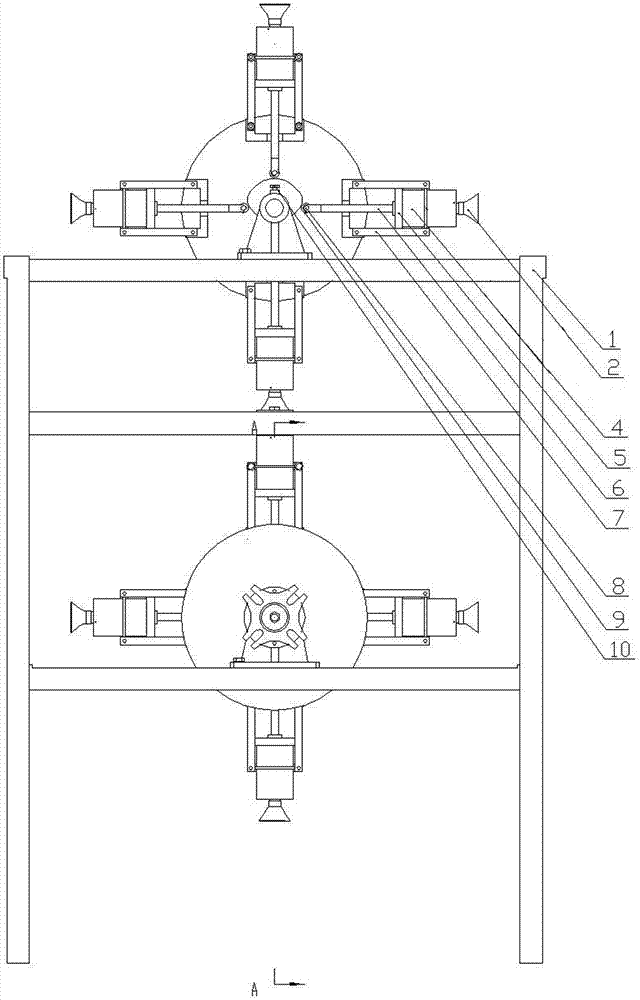

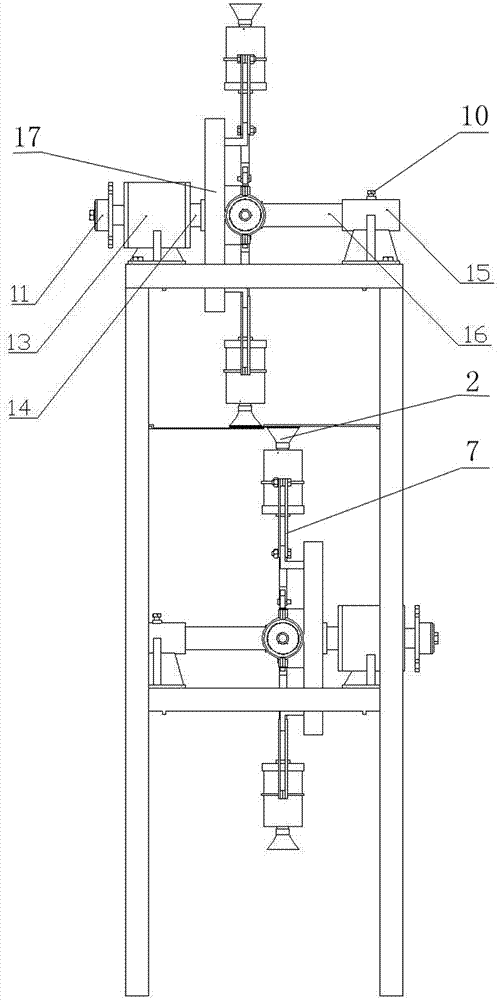

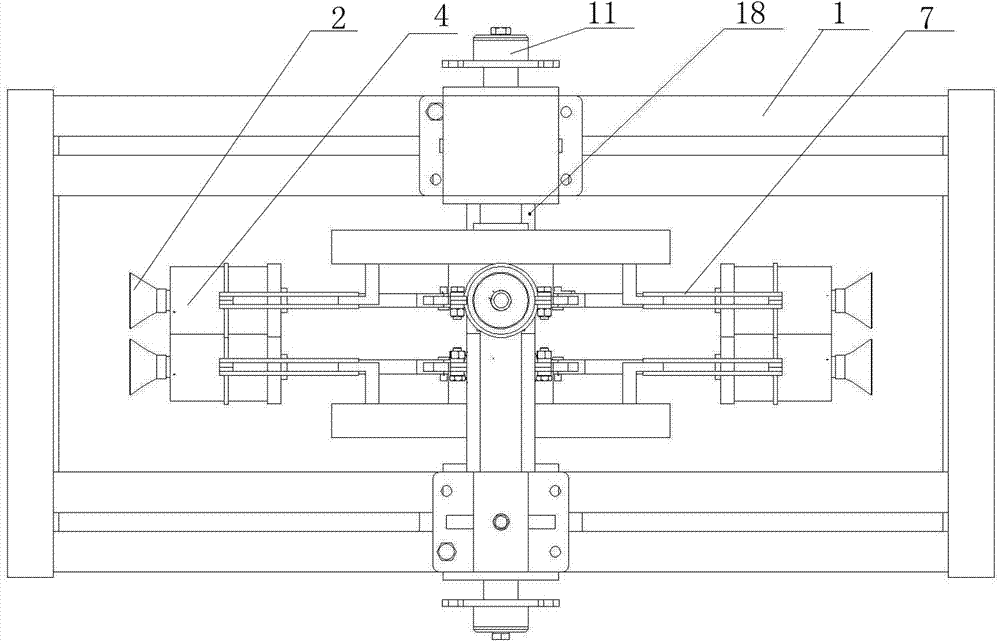

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as Figure 1-Figure 5 Shown, the present invention comprises frame 1, two suction bag devices and two plastic bag baffles 18, and described two suction bag devices and two plastic bag baffles 18 are installed on the frame 1, two suction bags The bag device is set up and down on the frame 1; the two plastic bag baffles 18 are located between the two suction bag devices, and there is a gap between the two plastic bag baffles 18, the size of which is 1.1 times the thickness of the betel nut packaging bag. -1.2 times.

[0018] Described suction bag device comprises rotating disk 17, rotating disk shaft 14, sucker 2, piston cylinder 4, cam 12 and camshaft 16; There are two angular contact ball bearings 131, and the turntable shaft 14 is supported on the two angular contact ball bearings 131. The outer end of the turntable shaft 14 is provided with a sheave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com