Material distributing system used for block machine

A technology of block forming machine and distribution system, which is applied to supply devices, manufacturing tools, etc., can solve the problems of insufficient distribution, reduced production efficiency, uneven distribution, etc., to facilitate material transportation, improve production efficiency, and prevent material corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

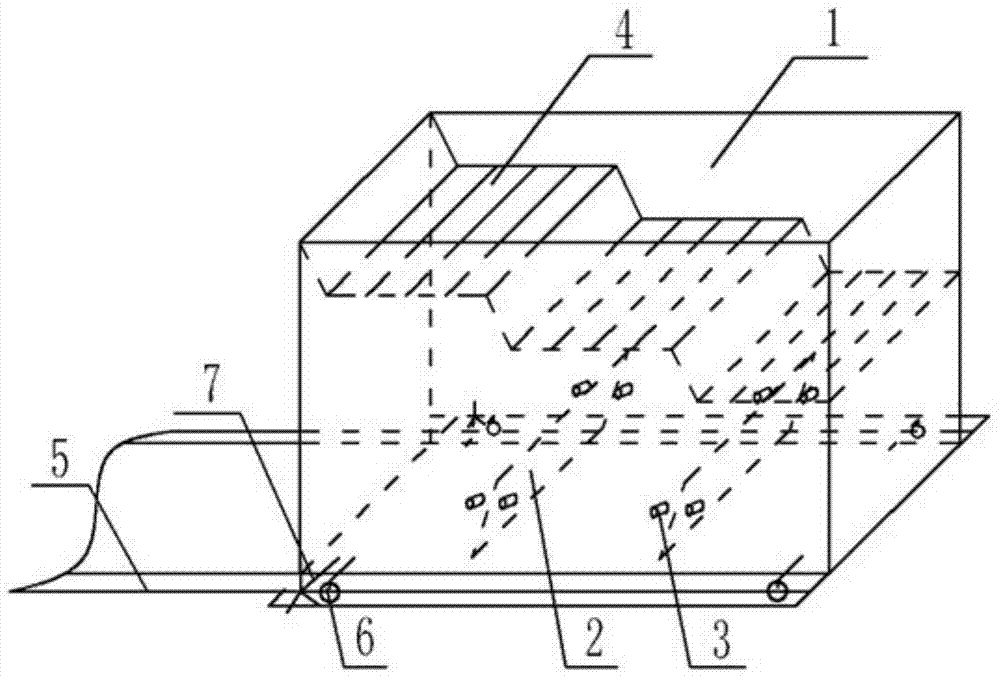

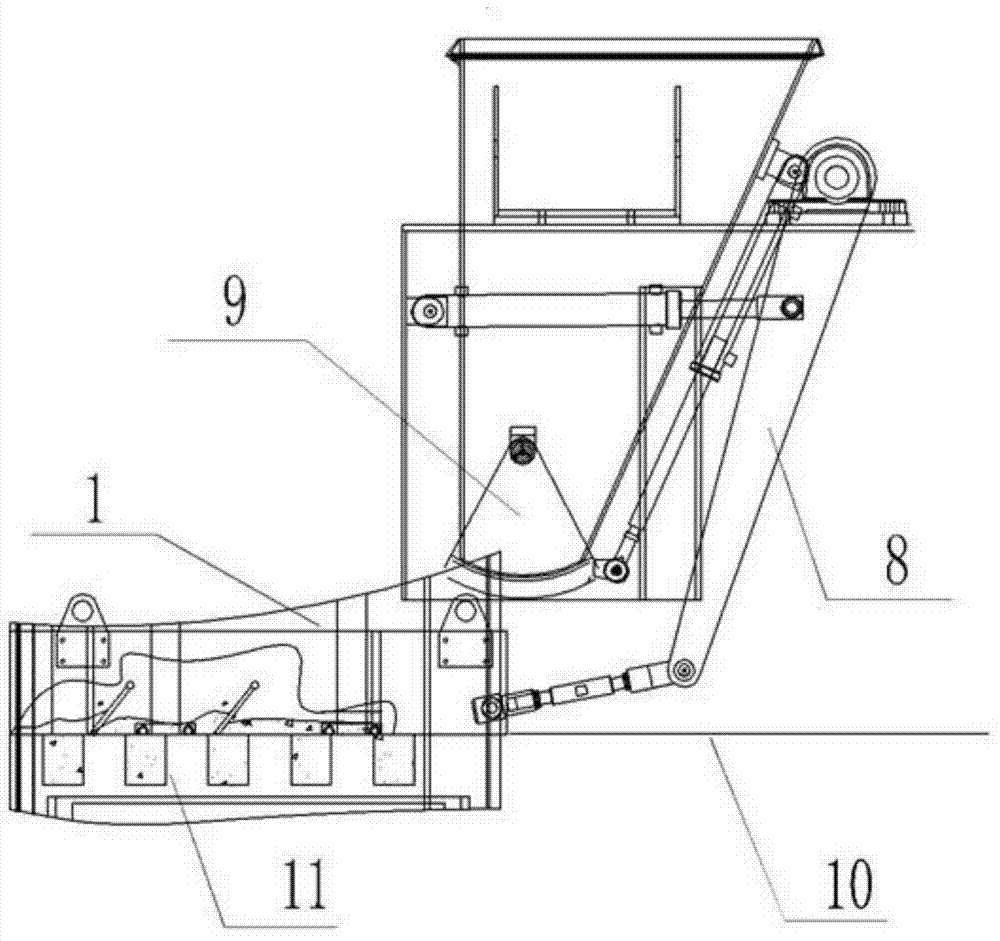

[0026] Such as figure 1 As shown in -2, a material distribution system for block forming machines, a hopper 9 for releasing materials is provided above the material distribution system, and a material loading platform 10 for carrying materials is provided below the material distribution system, and the material loading platform The mold box 11 of the block forming machine is seamlessly connected to the front of 10. The material distribution system moves forward under the push of the turning wall 8 to send materials into the mold box 11. The material distribution system includes a material distribution box that penetrates up and down 1. On the distribution box 1, at least a pair of pin shafts are arranged opposite to the two side walls parallel to the moving direction, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com