Manufacturing process of raw wood door

A technology for making wooden doors, which is applied in the field of making original wooden doors, can solve the problems of large investment and high price of original wooden doors, and achieve the effects of avoiding damage, reducing the probability of occupational diseases, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

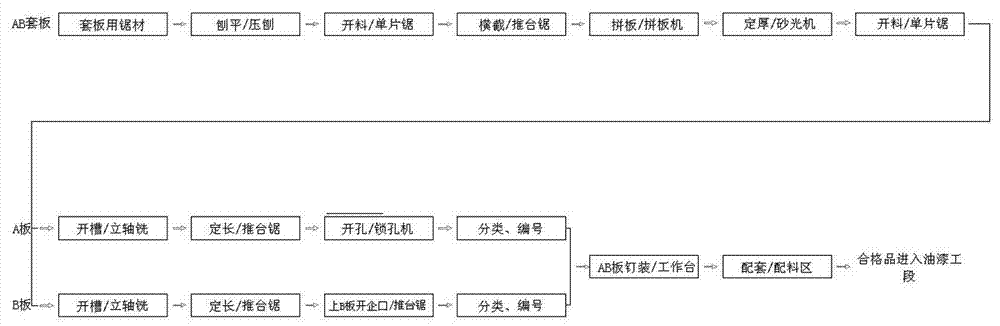

[0095] The present invention is a kind of manufacturing technology of original wooden door, and the manufacturing technology of original wooden door comprises the following steps:

[0096] (1) Prepare the door leaf, A board and B board and the door casing line at the same time,

[0097] The technological process of the door leaf includes

[0098] 1) Prepare vertical frame, horizontal frame and core board at the same time,

[0099] Wherein: the manufacturing process of vertical frame comprises the following steps:

[0100] A1. Vertical frame packing: use the sawn timber for the core layer, which is ordinary wood with a thickness of 32.5mm. The sawn timber for the core layer is planed by planing, and the planing thickness is 31mm. The sawn timber is processed by a single saw. Cutting, the width of the cutting is set according to the actual situation, and then the thickness is determined by sanding with a sander (door leaf thickness -9.5mm), and then cross-cut by a sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com