Improved sewage treatment PVDF thin film

An improved technology for sewage treatment, applied in osmosis/dialysis water/sewage treatment, membrane technology, semi-permeable membrane separation, etc., can solve the problems of ineffective anti-pollution performance and insufficient hydrophilic effect of sewage treatment , to achieve the effects of saving materials, enhancing pollution resistance, and increasing penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

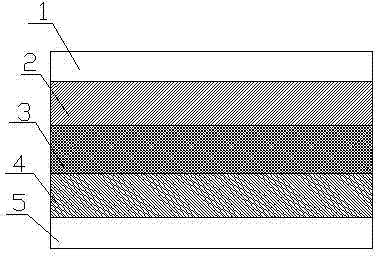

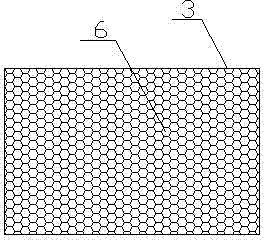

[0010] Such as figure 1 , figure 2 It is a structural schematic diagram of the present invention, an improved PVDF film for sewage treatment, including five layers, from top to bottom respectively upper PVDF film layer 1, Al 2 o 3 Nanoparticle layer 2, intermediate layer 3, TiO 2 The nano particle layer 4 and the lower PVDF film layer 5, the middle layer 3 is a honeycomb structure 6.

[0011] al 2 o 3 and TiO 2 The surface of the two kinds of nanoparticles is rich in hydroxyl groups and has a certain degree of hydrophilicity. When solidified, some holes will be formed at the interface. The existence of these holes also increases the connectivity between the membrane pores, so it can improve the permeability of the membrane. Hydrophilic. The honeycomb paper structure can not only save materials, but also play a role in heat insulation. Make the film last longer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com