Sieve roller counterflow cooler

A technology of countercurrent cooling and sieve rollers, which is applied in the field of coolers, can solve the problems of material arching, troublesome operation, uneven cooling of materials, etc., and achieve the effect of increasing the ventilation area, facilitating disassembly and replacement, and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments.

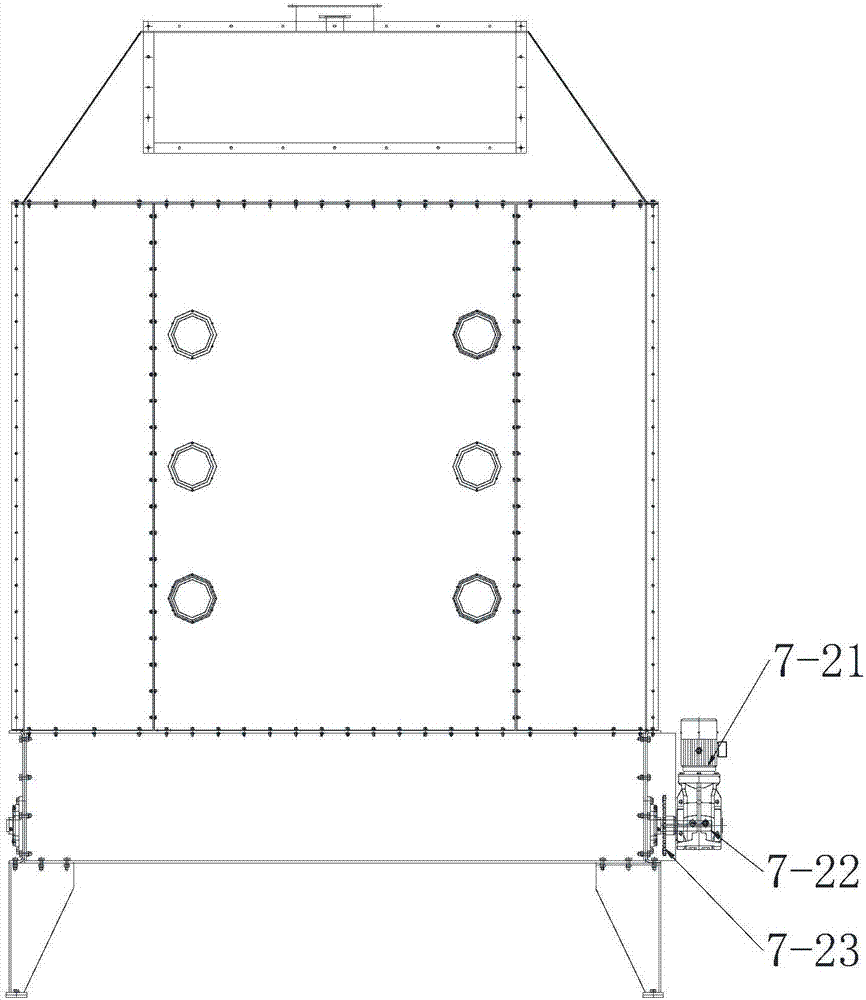

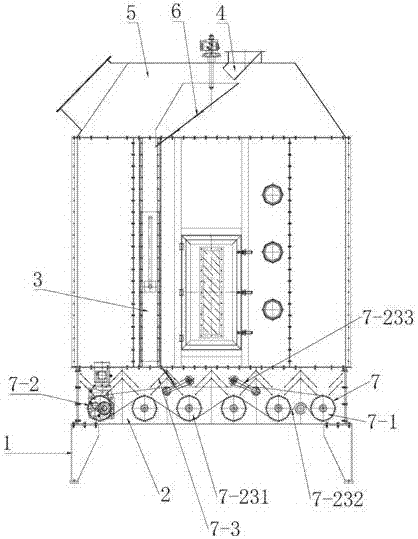

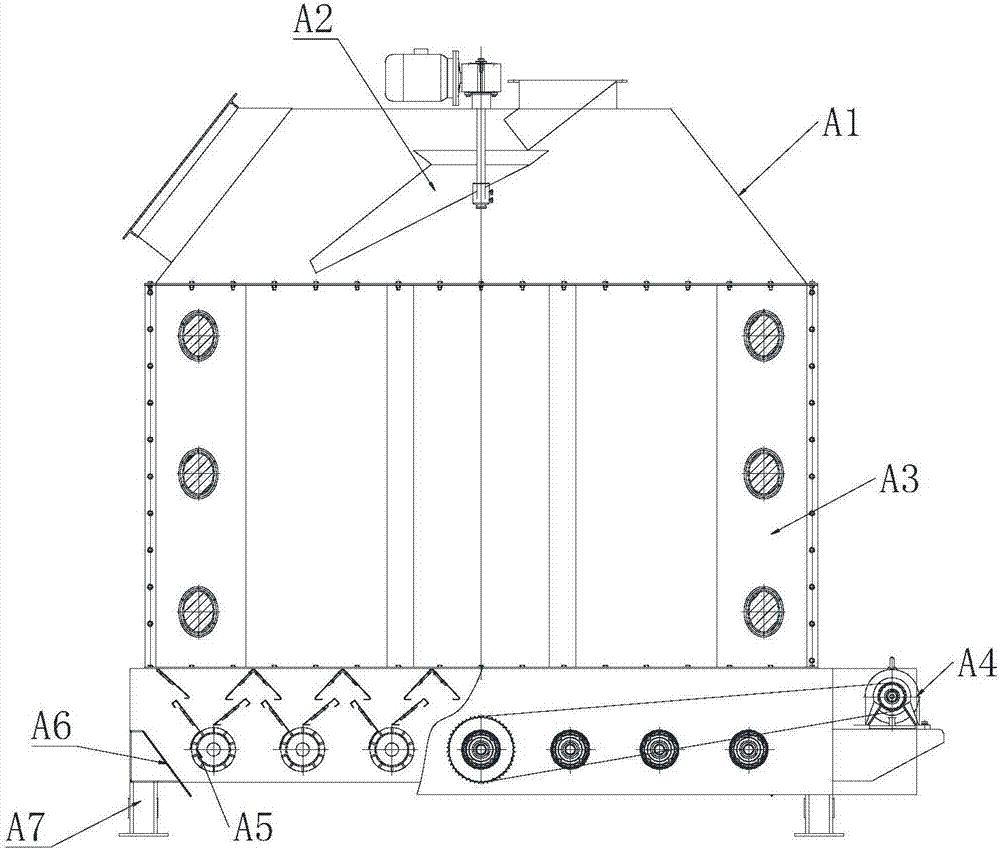

[0024] Such as Figure 1-Figure 5 As shown, the present invention is a sieve roller type countercurrent cooler, comprising a frame 1, a collection box 2, a cooling box 3, a feeder 4, an air outlet top cover 5, a bulk material device 6 and a discharge mechanism 7 , the air outlet top cover 5 is arranged on the top of the cooling box, the collection box 2 is arranged under the cooling box 3, the collection box 2 is arranged on the frame 1, and the discharge mechanism 7 is arranged in the collection box 2, The feeder 4, the air outlet top cover 5, and the bulk feeder 6 are respectively arranged above the cooling box. The cooling box is rectangular. There are arc-shaped plates 8 transitions between the adjacent two-side box plates. The arc-shaped plates It is assembled and fixed with the side box plate by split bolts to avoid uneven cooling of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com