Air spring module

一种空气弹簧、气囊的技术,应用在弹簧、车辆弹簧、弹簧/减震器等方向,能够解决不利、高成本、制造花费和安装花费、小可用结构空间等问题,达到简单安装的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

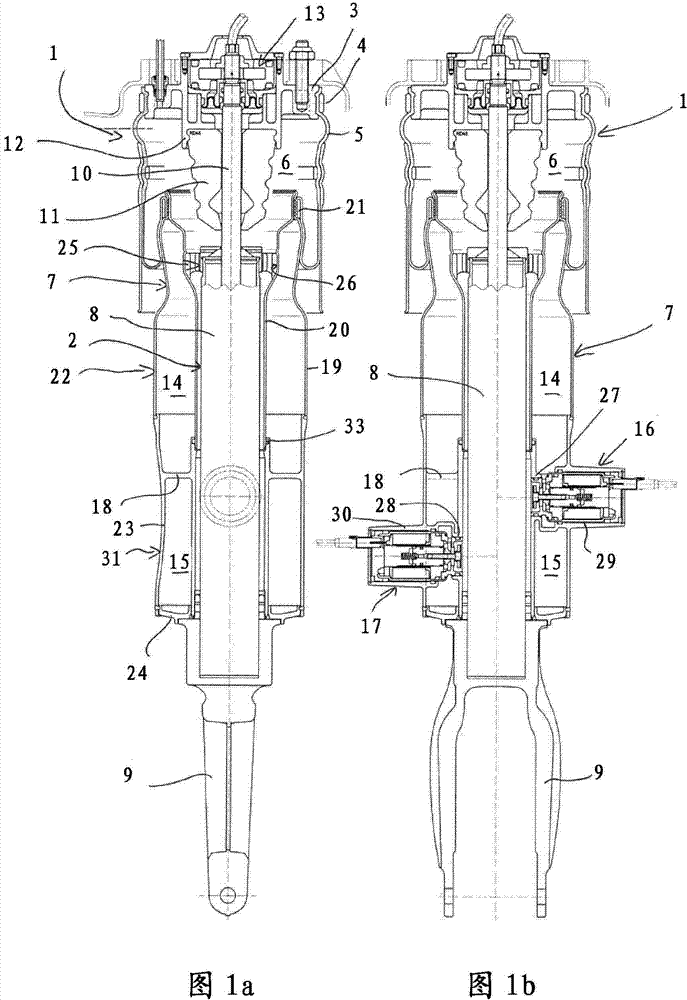

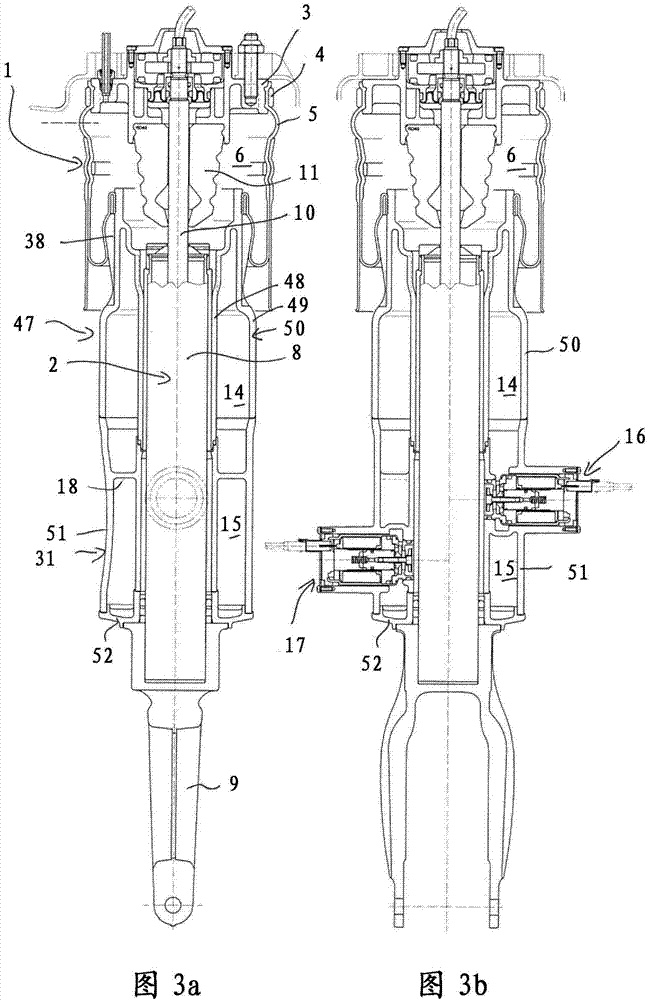

[0054] Figure 1a A part of a first exemplary embodiment of an air spring module is shown, which is known to comprise a shock absorber 2 and an air spring 1 for vibration isolation and damping of the chassis of a motor vehicle, preferably In a motor vehicle, the first end can be fixed relative to the body and the second end can be fixed to the wheel suspension. The air spring 1 comprises an air spring cover 3 fixed relative to the vehicle body, a first end of a rolling airbag 5 , which is fastened gas-tight to the air spring cover by means of a clamping element 4 , the coil The dynamic bladder at least partially delimits a first working or pressure chamber 6 filled with compressed air. The second end of the rolling airbag 5 is airtightly connected to the rolling piston 7 . The rolling airbag 5 can roll on this rolling piston 7, which is connected to the cylinder tube 8 of the shock absorber 2, wherein the cylinder tube 8 is preferably fixed to the shock absorber fork 9 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com