Resin composition, carbon fiber-reinforced composite material precursor obtained using the resin composition, carbon fiber-reinforced material, and carbon fiber-reinforced carbon material

A technology of resin composition and composite materials, applied in the direction of fiber chemical characteristics, conjugated synthetic polymer artificial filament, coating, etc., to achieve high flame retardancy and heat resistance, excellent bending strength and bending modulus of elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0050]In addition, a representative production example of SMC as a precursor is given. First, using a known SMC production device, the above-mentioned resin composition is made to have a substantially uniform thickness in the range of about 0.3 to 2.0 mm. After coating on the upper and lower carrier films, spread a specified amount of carbon fibers cut to a specified length on the paste coated on the lower carrier film, and then use the paste coated on the upper and lower carrier films An agent (resin composition) sandwiches the scattered carbon fibers, and then passes the whole body between impregnating rolls to impregnate the carbon fibers with the resin composition, and then performs aging treatment as necessary to obtain the target precursor. In addition, here, as a carrier film, a polyethylene film, a polypropylene film, etc. are normally used. In addition, aging treatment is one of the pretreatments before molding, and when performing this aging treatment, a method of pe...

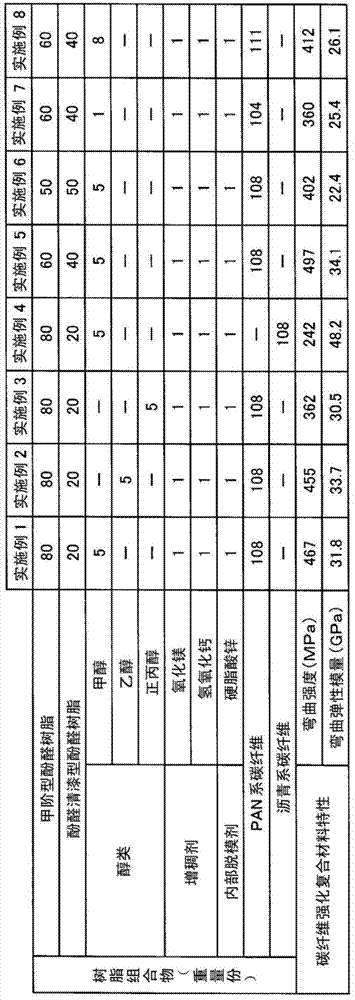

Embodiment 1

[0058] 80 parts by mass of a resol type phenolic resin (manufactured by Asahi Organic Material Industry Co., Ltd., AKP-012) with a water content measurement result of 20.5% and a number average molecular weight of 362 by the Karl Fischer method and 1,000 parts by mass of 20 parts by mass of a novolak-type phenolic resin (manufactured by Asahi Organic Materials Co., Ltd., SP1010) was stored in a container, and mixed and stirred for about 5 minutes with a mixer. Next, 5 parts by mass of methanol as an alcohol was put into the container, and the mixture was further mixed and stirred for about 3 minutes with a mixer. Then, 1 mass part of magnesium oxide as a thickener, 1 mass part of calcium hydroxide, and 1 mass part of zinc stearate as an internal mold release agent are respectively dropped into a container, mixed and stirred for about 3 minutes with a mixer, and the This yields the target resin composition.

[0059] Next, 108 parts by mass of carbon fibers were impregnated wit...

Embodiment 2~3

[0064] Except that the alcohol contained in the resin composition was changed to ethanol or n-propanol, a resin composition was prepared in the same manner as in Example 1, and a carbon fiber reinforced composite material was produced in the same manner as in Example 1 using the resin composition. (and its precursor), then, its bending strength and flexural modulus were measured in the same manner as in Example 1, and the results of each measurement were collectively shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com