Radio and axial hybrid magnetic circuit permanent-magnet synchronous-side rotor motor

A permanent magnet synchronous, rotor motor technology, applied in synchronous motors with stationary armatures and rotating magnets, synchronous machines, synchronous machine parts, etc. The effect of rapid increase in eddy current loss, elimination of ends, and increased torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

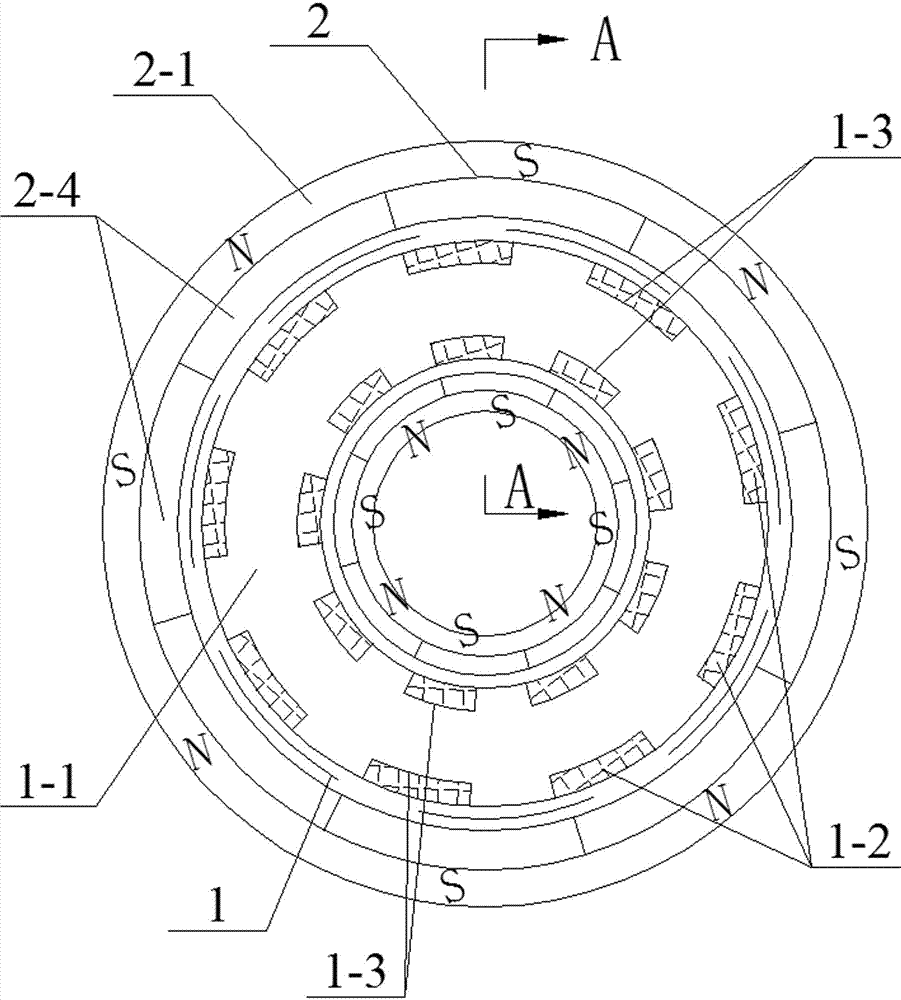

[0012] Specific implementation mode one: combine figure 1 and figure 2 As shown, it consists of stator 1 and rotor 2;

[0013] The stator 1 is composed of a solid ring 1-1 and a plurality of windings 1-2; the solid ring 1-1 has a plurality of rectangular ring slots 1-3 along the radial direction of the ring, and all the rectangular ring slots 1-3 are in the The upper circumference of the solid ring 1-1 is uniformly arranged; each rectangular ring groove 1-3 is embedded with a winding 1-2, and the material of the solid ring 1-1 is soft magnetic composite material SMC; the rotor 2 is made of magnetically conductive Outer ring 2-1, magnetically conductive side disc 2-2, magnetically conductive inner ring 2-3, and multiple pieces of magnetic steel 2-4; magnetically conductive inner ring 2-3 is arranged on magnetically conductive outer ring 2 Inside -1, the outer circular edge of the magnetically conductive side disc 2-2 is covered on the left port of the magnetically conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com