Linear motion device in combined mode

A technology of linear motion and combined mode, which is applied in the direction of electromechanical devices, electric components, and control of mechanical energy. It can solve the problems of large space occupied by flanged nuts, unattractive appearance, and complicated structure, and achieve compact design and structural optimization. , the effect of light weight of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

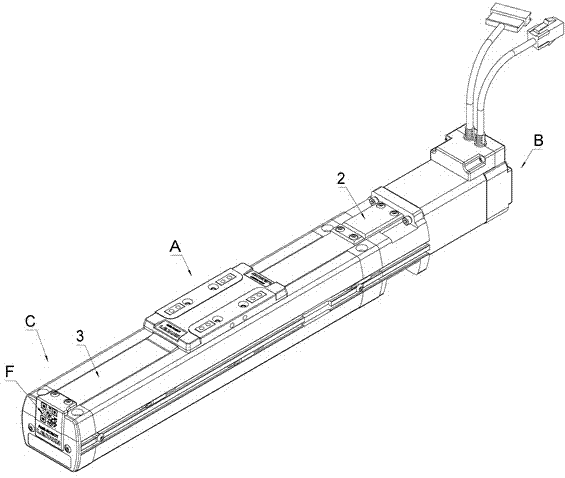

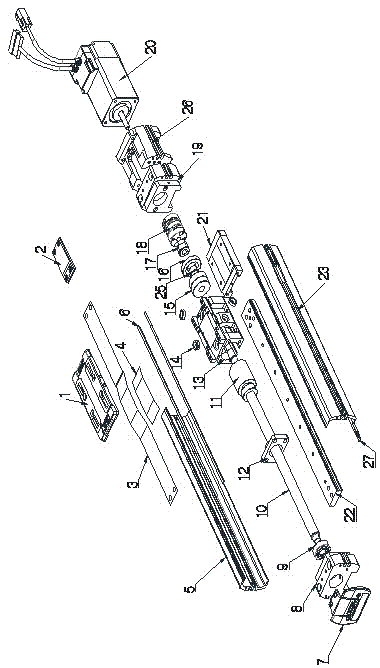

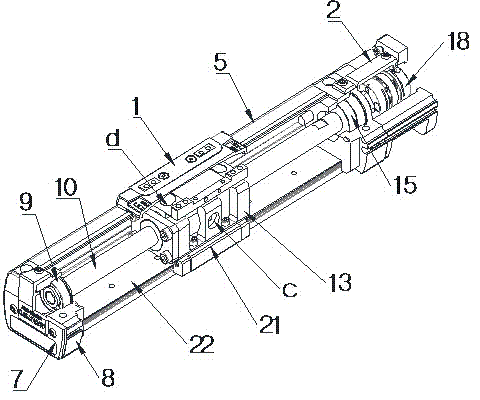

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described, as figure 1 , 2 , 3, the combined mode linear motion device includes a drive element (B), a transmission element (A), a housing (C) and a dust-proof sealing structure (b). The fixed end of the lead screw (10) is fixed to the inside of the fixed shaft seat (8) through the bearing (9), the threaded nut (11) is screwed into the lead screw (10), and the threaded nut is screwed into the threaded nut through the flange (12) (11) and fixed on the slide table (13), the supporting end bearing (15) of the lead screw (10) is fixed in the supporting bearing seat (19) through the round nut (16) and the lock nut (17), And connect the end of the lead screw (10) with the shaft of the drive element (B) motor (20) through a shaft coupling (18).

[0023] Wherein the side plates (5, 23), the fixed end bearing housing (8), the supporting end bearing housing (19), and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com