Air separator for refrigeration system

An air separator and refrigeration system technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of large resistance along the process, many connecting elbows, and large loss of refrigerant, so as to reduce the resistance along the process, Improve work efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

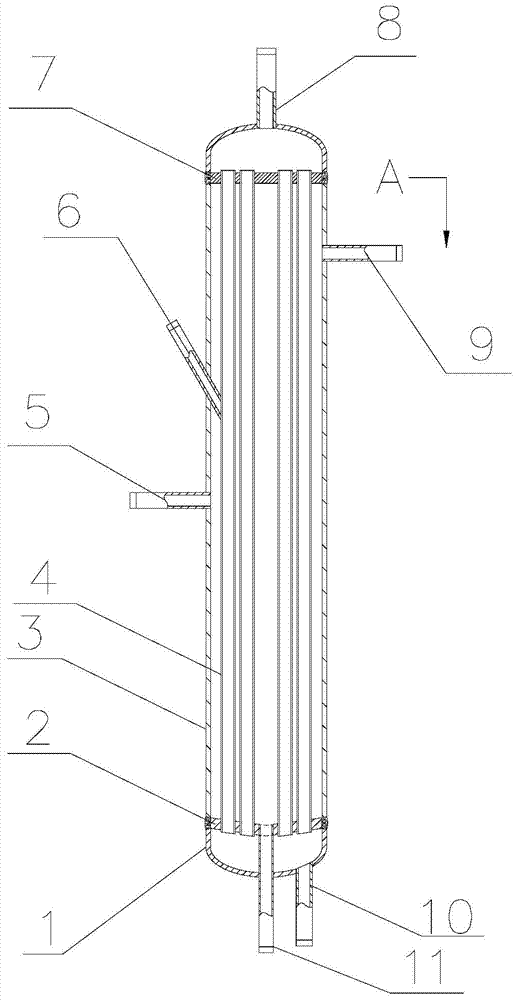

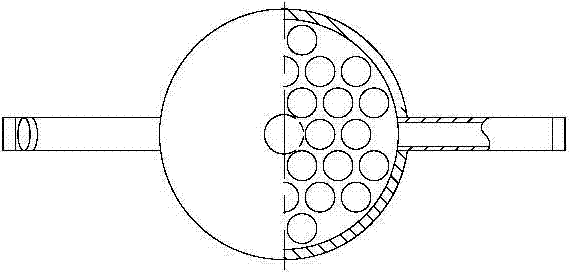

[0024] The air separator of the present invention belongs to heat exchange and purification equipment, and is suitable for removing air and other non-condensable gases in a refrigeration system. The invention improves on the shortcomings of the traditional quadruple sleeve type and spiral heat exchange tube type air separators, and mainly improves the heat exchange elements in the shell into heat exchange tubes with compact structure and triangular arrangement. Compared with the traditional air separator, it reduces the occupied space of the air separator, increases the condensation heat exchange area, improves the condensation cooling efficiency, and speeds up the discharge of non-condensable gas. In addition, the invention has the advantages of simple structure, easy manufacture, long service life, and wide application range. Using the high-efficiency air separator designed by the invention can enhance the heat exchange and purification capacity of the refrigeration system an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com