Plastic assembling module for rainwater collection and storage

A technology of rainwater collection and plastic assembly, applied in water supply devices, drinking water devices, general water supply conservation, etc., can solve pressure bearing capacity, water storage ratio, unsatisfactory cost, difficulty in popularization and use, and reduce the cost of living quarters and public greening industries Water consumption of tap water and other issues, to meet the requirements of use, low production cost, to ensure the effect of lateral pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

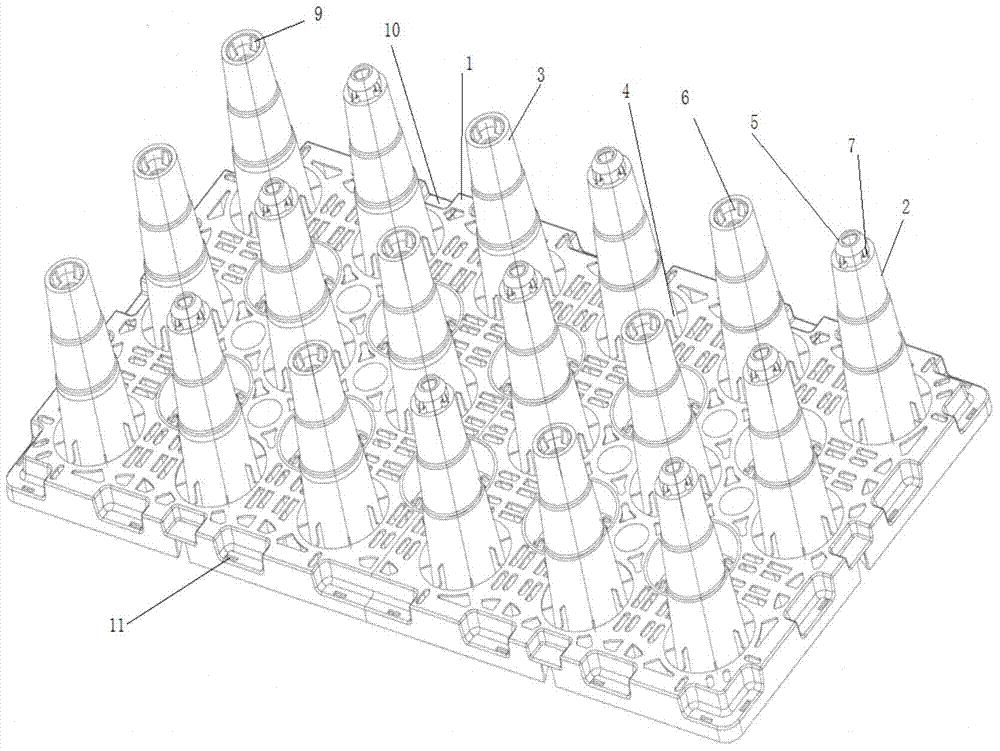

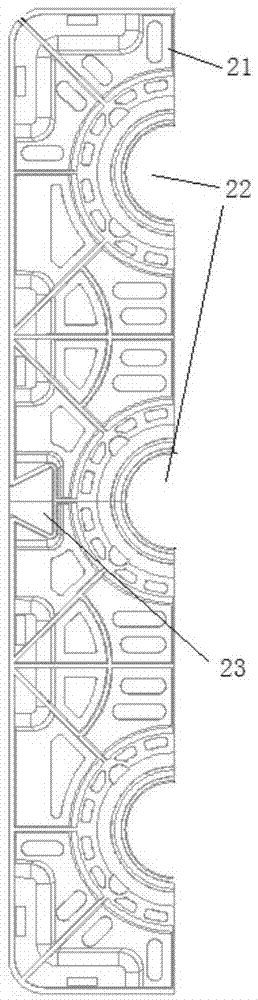

[0014] Such as Figure 1-2 Shown: bottom plate 1, bearing column 2, bearing column small end 3, bearing column large end 4, bearing column small end shank column 5 bearing column small end tenon 6, elastic piece 7, small groove 9, side Plate mounting holes 10, side plate mounting hole slots 11, ribs 21, bearing column clamping holes 22, side plate mounting grooves 23.

[0015] The modular unit includes a pair of upper and lower plastic monomers, the base plate 1 and 5 rows of load-bearing columns 2 arranged on the base plate; the base plate 1 is equipped with five rows of load-bearing columns, and the first, third, and fifth rows are neat and orderly Arrangement, six load-bearing columns are evenly distributed in each row; the load-bearing columns of the second and fourth rows are between the first and third rows and the third and fifth rows, and each column of the second and fourth rows of load-bearing columns is arranged in the first , Three, and five permutations.

[0016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com