Inflaming retarding working solution and inflaming retarding finishing method of pure cotton fabric and/or cotton-polyester blended fabric

A technology of flame retardant finishing and polyester-cotton blending, which is used in flame-retardant fibers, textiles and papermaking, fiber processing, etc. Intense, flammability-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

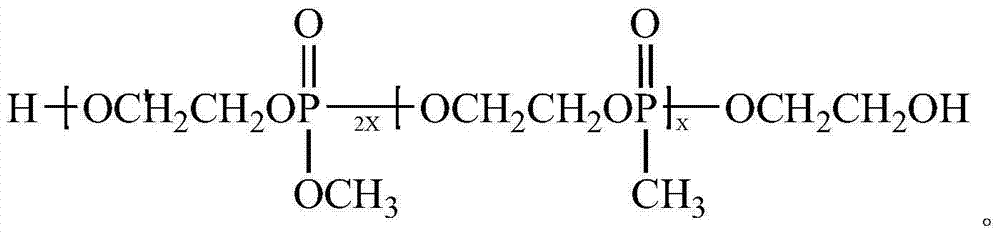

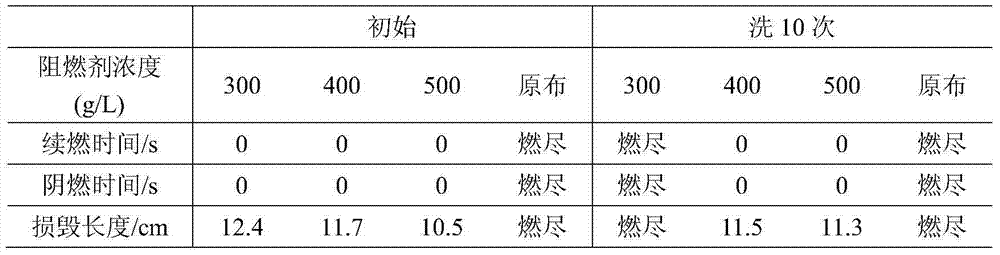

[0031] Embodiment 1. Comparison of different dosages of flame retardants

[0032] In this example, the applicant tested different dosages of flame retardants in the flame retardant working fluid of the present invention.

[0033] In this embodiment, the flame retardant working fluid includes the following components: a flame retardant and a crosslinking agent, and the rest is water, the concentration of the flame retardant is 300-600 g / L, and the concentration of the crosslinking agent is 80g / L. Wherein, the flame retardant is formed by mixing the flame retardant Pyrovatex HP and the cyclic phosphate flame retardant in a mass ratio of (1-4):1; the crosslinking agent is 2D resin.

[0034] In this example, the cloth sample is made of polyester-cotton card (116×46, 20 s ×16 s , blending ratio 50:50).

[0035] The flame retardant finishing is as follows: dip the cloth sample twice in the flame retardant working solution, dry it at 100°C, and bake it at 150°C for 3 minutes; the...

Embodiment 2

[0040] Embodiment 2. stacking method flame retardant finishing method

[0041] In this embodiment, the applicant tested the stacking flame retardant finishing method of the present invention.

[0042] In this embodiment, the flame retardant working solution includes the following components: a flame retardant and a crosslinking agent, and the rest is water, the concentration of the flame retardant is 600 g / L, and the concentration of the crosslinking agent is 80 g / L. Wherein, the flame retardant is formed by mixing the flame retardant Pyrovatex HP and the cyclic phosphate flame retardant in a mass ratio of 2:1; the crosslinking agent is 2D resin.

[0043] In this example, the cloth sample is made of polyester-cotton card (116×46, 20 s ×16 s , blending ratio 50:50).

[0044] The flame retardant finishing is as follows: dip the cloth sample twice in the flame retardant working solution, stack it for 16 hours, and bake it at 150°C for 4 minutes; then wash it in hot water, cold...

Embodiment 3

[0050] Example 3. Durability of flame retardant effect

[0051] In this example, the applicant tested the flame-retardant effect and durability of the polyester-cotton blended fabric after being flame-retardantly finished by the flame-retardant working fluid of the present invention.

[0052] In this embodiment, the flame retardant working fluid contains the following components: a flame retardant and a crosslinking agent, and the rest is water. The concentration of the flame retardant is 600 g / L, and the concentration of the crosslinking agent is 80 g / L. L. Wherein, the flame retardant is formed by mixing the flame retardant Pyrovatex HP and the cyclic phosphate flame retardant in a mass ratio of 2:1; the crosslinking agent is 2D resin.

[0053] In this example, the cloth sample is made of polyester-cotton card (116×46, 20 s ×16 s , blending ratio 50:50).

[0054] The flame retardant finishing is as follows: dip the cloth sample twice in the flame retardant working soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damage length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com