Production process method for micro self-brewing special beer malt wort dry powder

A wort and self-brewing technology, which is applied in the preparation of wort, beer brewing, biochemical equipment and methods, etc., can solve the problems of single beer variety, single flavor, and unsatisfactory beer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

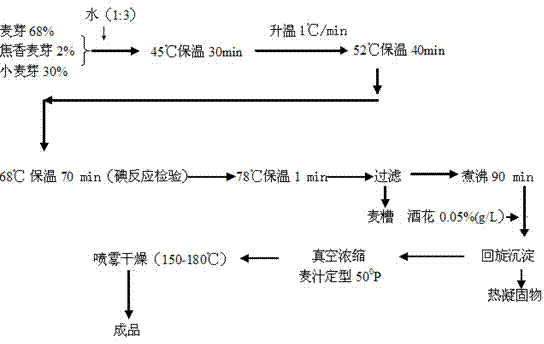

[0015] Implementation case 1, the production method of wort dry powder used for brewing cloudy wheat beer

[0016] (1) Raw material preparation: according to the formula of 20-50% of wheat malt, 50-80% of barley malt, and 2% of caramel malt, the raw materials are prepared and pulverized;

[0017] (2) Preparation of malt mash: According to the ratio of material to water 1:3, stir while adding water, raise the temperature of the mash to 45°C, keep it for 30 minutes, raise the temperature of the mash to 52°C, keep it for 20 minutes, raise the temperature to 68°C and keep it for 70 minutes to complete Malt saccharification to obtain malt mash;

[0018] (3) Wort stereotypes: mash mash filter to remove wheat grains, take wort, wort heat up to boiling, add hops at 0.05%-0.2% (g / L), boil for 90-120min, wort stereotypes 10-12 °P;

[0019] (4) Whirlpool precipitation: Wort wort whirlpool precipitation for 30 minutes to remove thermal coagulation;

[0020] (5) Vacuum concentration: p...

Embodiment example 2

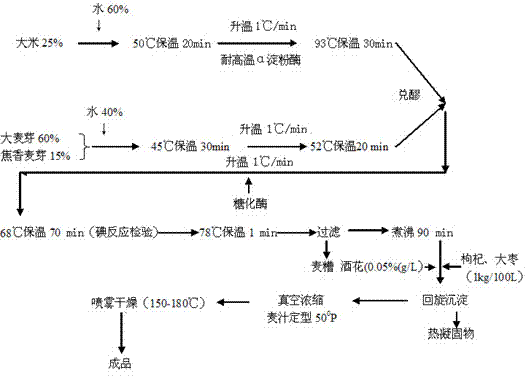

[0023] Implementation case 2, the production method of wort dry powder used in brewing health-care red beer

[0024] (1) Material preparation: prepare materials according to the formula of barley malt 60-70%, rice 25-15%, and caramel malt 15%, and pulverize;

[0025] (2) Preparation of gelatinized mash, use crushed rice or cornstarch according to the material-water ratio of 1:4, stir while adding water, raise the temperature of the mash to 50°C, keep it warm for 20min for protein hydrolysis, add 100U / g starch for resistance High-temperature α-amylase, and heat up to 93°C, keep warm for 30min, complete gelatinization to obtain gelatinized mash;

[0026] (3) Preparation of malt mash: Use crushed barley malt and caramel malt according to the material-to-water ratio of 1:3, stir while adding water, raise the temperature of the mash to 45°C, keep it warm for 30 minutes, raise the temperature of the mash to 52°C, and keep it warm 20min to make malt mash;

[0027] (4) Preparation...

Embodiment example 3

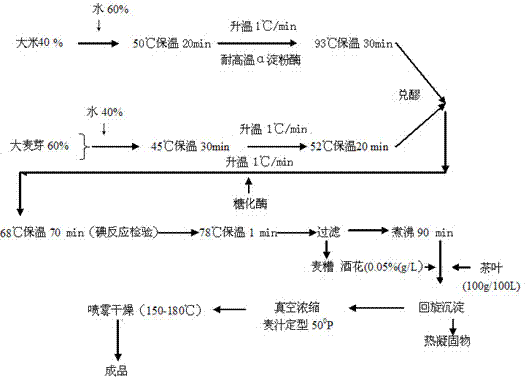

[0033] Implementation case 3, production method of dry wort powder used for brewing tea beer

[0034] (1) material preparation: according to the formula of 60-70% barley malt and 40-30% rice, prepare materials and pulverize;

[0035] (2) For the preparation of gelatinized mash, use crushed rice or cornstarch at a material-to-water ratio of 1:4, stir while adding water, raise the temperature of the mash to 50°C, and keep it warm for 20 minutes for protein hydrolysis; add 100U / g starch to resist High-temperature α-amylase, and heat up to 93°C, keep warm for 30min, complete gelatinization to obtain gelatinized mash;

[0036] (3) Preparation of malt mash: Use crushed barley malt and caramel malt according to the material-to-water ratio of 1:3, stir while adding water, raise the temperature of the mash to 45°C, keep it warm for 30 minutes, raise the temperature of the mash to 52°C, and keep it warm 20min to make malt mash;

[0037] (4) Preparation of saccharification mash: blen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com