Anti-deformation device for extruder

An anti-deformation and extruder technology, applied in the field of extruder auxiliary devices, can solve the problems of abandonment and recycling, failure to meet finished product requirements, waste of resources, etc., and achieve the effects of reducing production costs, simple structure, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

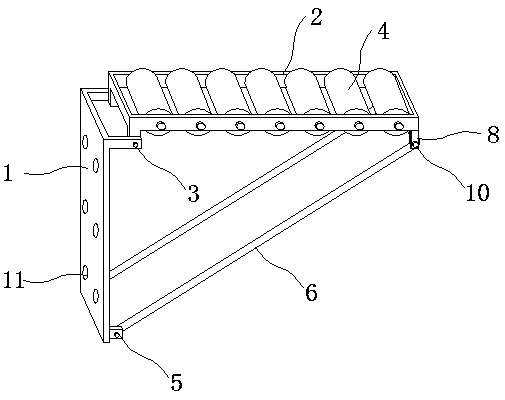

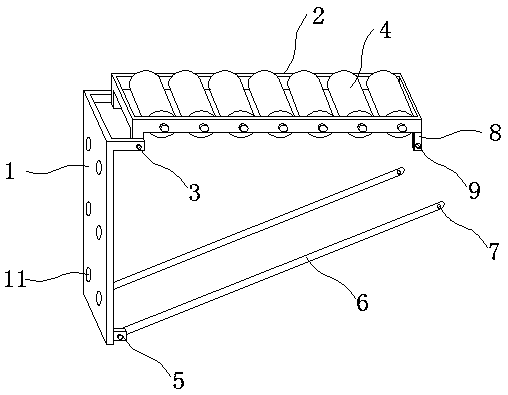

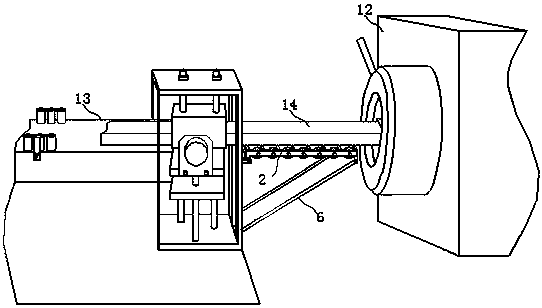

[0011] Attached below figure 1 , attached figure 2 And attached image 3 The anti-deformation device for an extruder of the present invention will be further described.

[0012] The anti-deformation device for an extruder of the present invention is composed of a fixed suspension beam 1 and a cross arm 2, and is characterized in that the suspension beam 1 is a cuboid plate, and the top end is connected to one end of the cross arm 2 through a hinge I3, and the cross arm 2 is Frame type, its interior is horizontally connected with the transmission roller 4 sequentially, the lower hinge II5 of the suspension beam 1 is connected with two support rods 6, the front ends of the support rods 6 are provided with radial through holes I7, and the lower front ends of the cross arm 2 are provided on both sides. There is a bump 8, and the bump 8 is provided with a through hole II9, and the through hole I7 and the through hole II9 are interspersed and fixed by the fixing rod 10, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com