An automatic demoulding device

A technology of automatic demoulding and demoulding mechanism, which is applied in the direction of unloading devices and manufacturing tools, can solve the problems of poor surface forming quality of insulation board blanks, adhesion between molds and insulation board blanks, and increased labor intensity of insulation boards. Achieve the effect of avoiding manual demoulding, small footprint and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

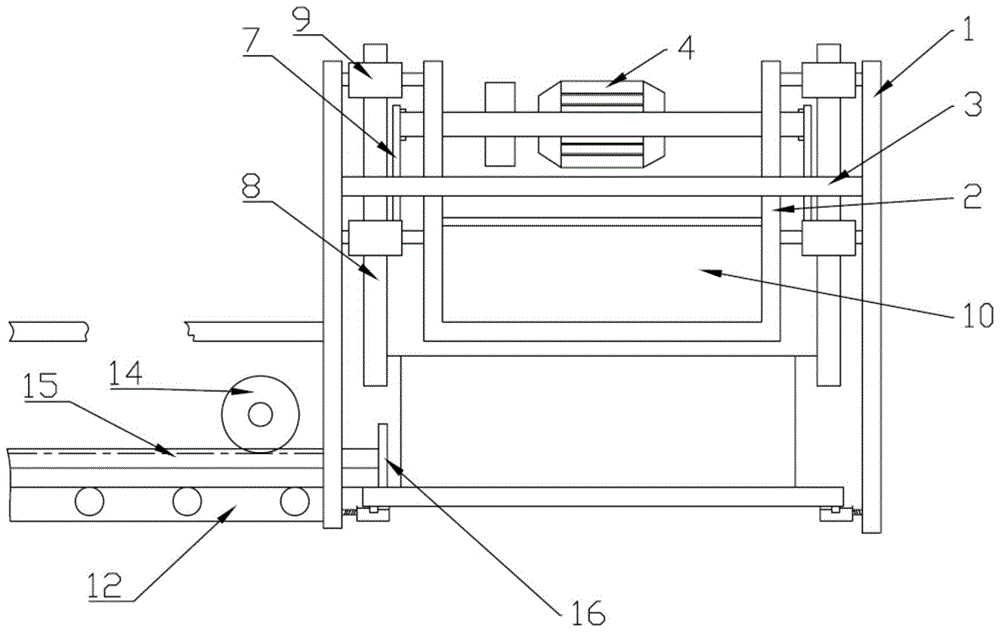

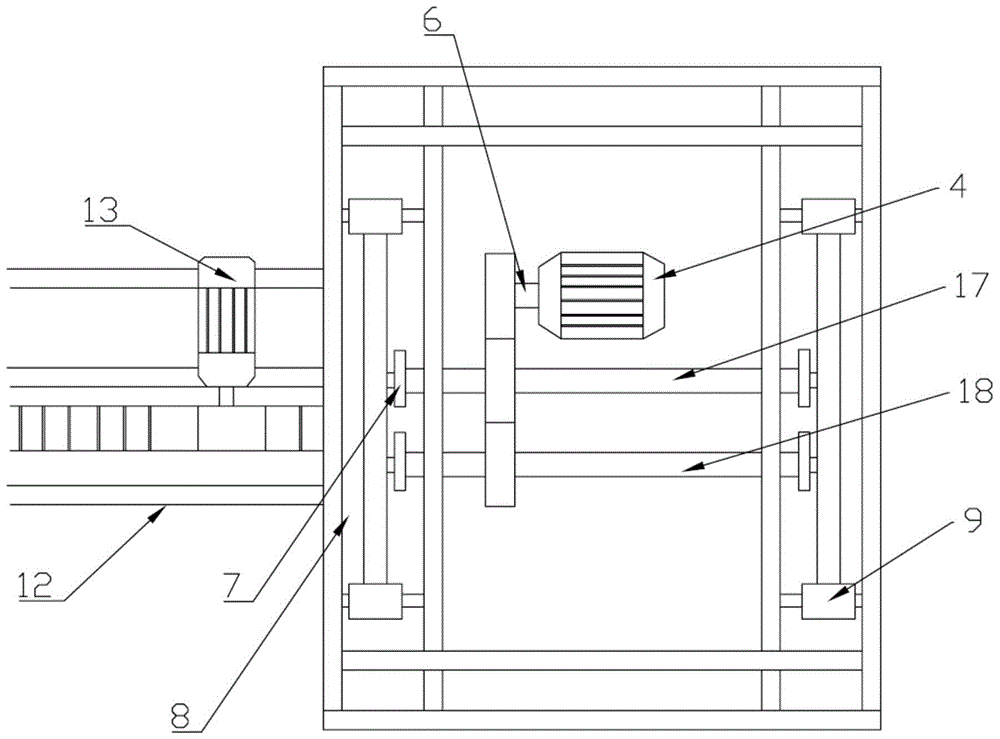

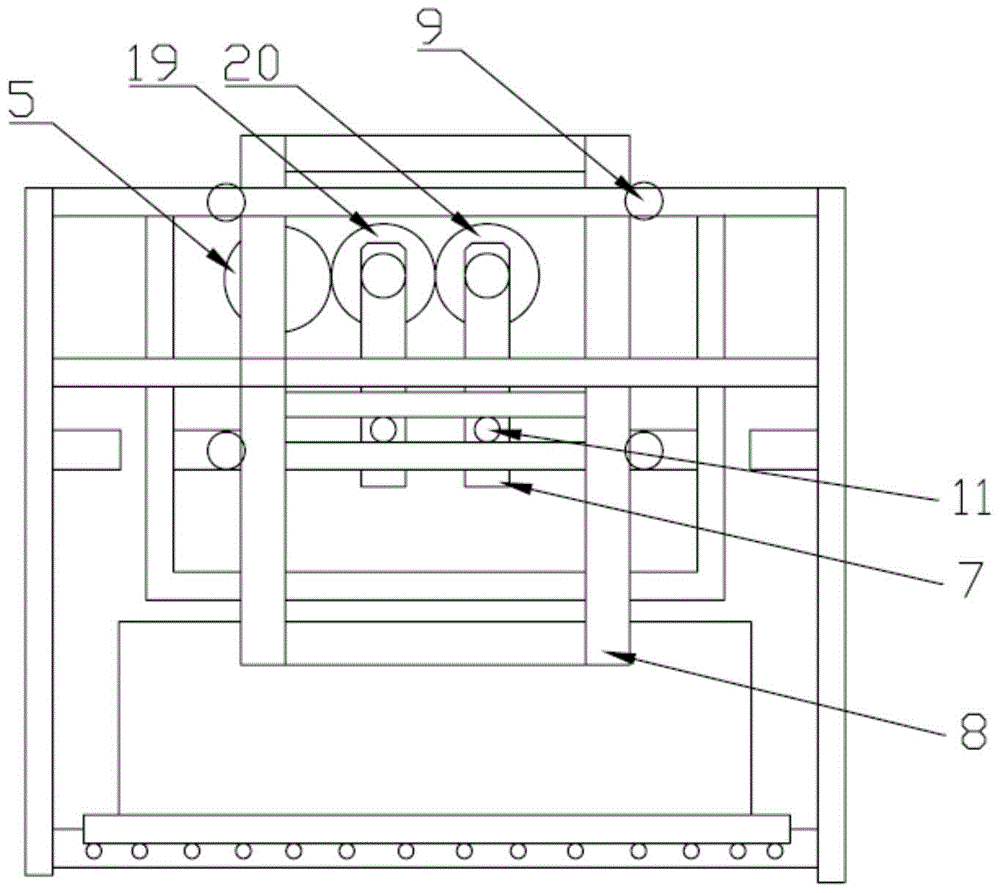

[0030] Such as Figure 1-Figure 6 As shown, an automatic demoulding device includes a demoulding mechanism and a pushing mechanism, the described demoulding mechanism is arranged on the upper part of the mold to be stripped, and the described pushing mechanism is arranged on one side of the mold to be stripped, the described The demoulding mechanism includes outer frame 1, inner frame 2, flat frame 3, reducer 4, power main gear 5, transmission gear, power shaft 6, transmission shaft, eccentric frame 7, lifting arm 8, guide wheel 9 and top pressure head 10;

[0031] The transmission shaft is arranged on the inner frame 2, and the flat frame 3 is arranged on the upper side of the outer frame 1, and is fixedly connected with the outer frame 1 and the inner frame 2 respectively. The lower part of the inner frame 2 is provided with a pressing head 10, and the position of the bottom end of the pressing head 10 is consistent with the position of the material;

[0032] Described red...

Embodiment 2

[0040] The difference from Embodiment 1 is that the transmission shaft is a shaft, and the reduction gear 4 drives the power main gear 5 on the power shaft 6 to rotate, and the power main gear 5 drives the transmission gear to rotate, thereby driving the transmission shaft rotate.

[0041]The working process and principle of the present invention are: when not working, the lifting arm 8 of the demoulding mechanism is in a descending state, and when the mold on the production line track reaches below the demoulding mechanism, the presence or absence of mold detectors arranged on the production line will be at this time The mold is detected, and the detection signal is sent to the control device. The control device (PLC or single-chip microcomputer) controls the operation of the reducer 1 in the demoulding mechanism, thereby driving the drive shaft to run, driving the eccentric frame 7 at both ends of the drive shaft to rotate, and the eccentric The linkage 11 at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com