A double-tube automatic slag feeder for wide slab crystallizer

An automatic slag adding machine and crystallizer technology, which is applied in the field of continuous casting mold slag automatic feeding equipment, can solve the problems affecting the surface and internal quality of the slab, the randomness of artificial slag adding, and the uneven thickness of the slag layer, etc., to achieve Light weight, simple structure, uniform effect of slag addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, without limiting the scope of protection.

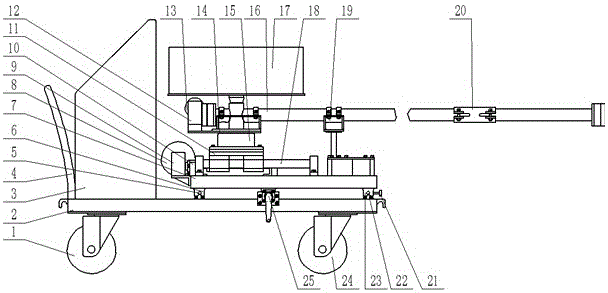

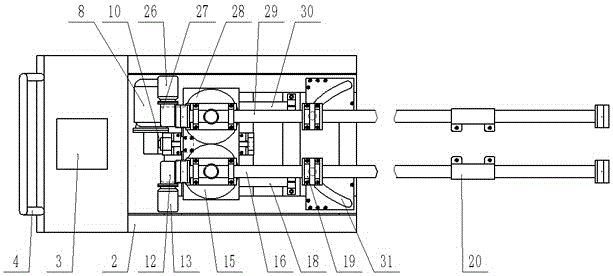

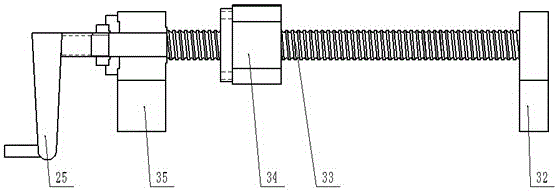

[0024] A double-tube automatic slag adding machine for a wide slab crystallizer, the slag adding machine is as figure 1 and figure 2 As shown, it consists of three parts: the frame, the fine-tuning centering mechanism, the rectangular compensation mechanism for the cloth area, the slag adding mechanism and the electronic control system; the electronic control system, the fine-tuning centering mechanism and the rectangular compensation mechanism for the cloth area are installed on the frame. On the top, the slag adding mechanism is installed on the rectangular compensation mechanism of the cloth area.

[0025] The vehicle frame comprises: handrail 4, vehicle base 2, two front wheels 24 and two rear wheels 1; The two ends of the wheel 1 and the vehicle base 2 are provided with fixed lifting hooks.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com