Combined hydraulic cylinder roller disassembling mechanism

A technology of hydraulic cylinder and cylinder block, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of low efficiency and inability to replace the roll ring separately, and achieves simple operation, compact structure, satisfying Use the desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

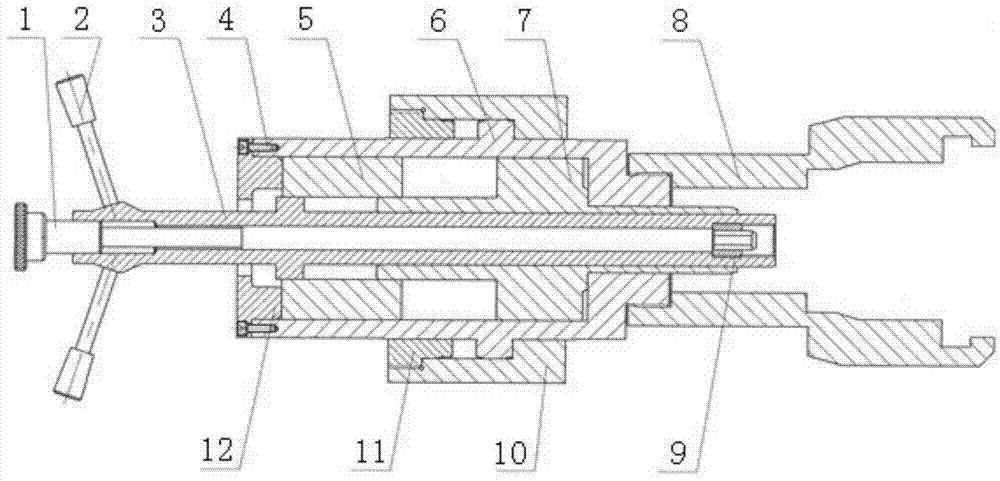

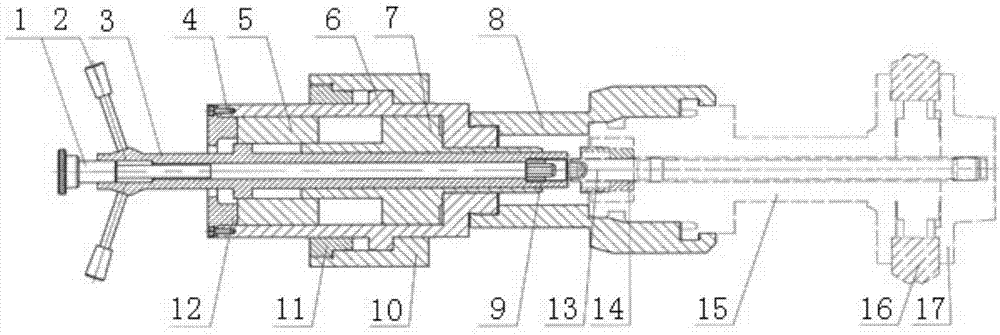

[0016] see figure 1 , the combined hydraulic cylinder unloading mechanism, including the first piston 6 as the cylinder, the second piston 7 is installed in the inner hydraulic cylinder formed in the first piston 6, the first piston 6 is provided with a cylinder 10, and the cylinder 10 passes through The bolt is connected to the spreader, and forms an outer hydraulic cylinder with the first piston 6. The first piston 6 is fixedly connected with the clamp 8 to transmit the pulling force to pull out the roll assembly. The rod sleeve 3 runs through the second piston 7, and the inside of the rod sleeve 3 A long rod 1 is assembled, and the right end of the long rod 1 is connected with the inner and outer hexagons of the nut 9, and the nut 9 is fixedly connected with the rod sleeve 3 by threads to locate the long rod 1.

[0017] The rod sleeve 3 is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com