Floatation reagent used for separating gold from antimony

A flotation reagent and flotation technology, applied in flotation, solid separation, etc., can solve the problem of ineffective separation of gold and antimony, and achieve the effect of low price and improved separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] This agent is to dissolve sodium sulfite, sodium humate and potassium permanganate in water at a mass ratio of 50:25:25, and add it as usual after standing for 48 hours.

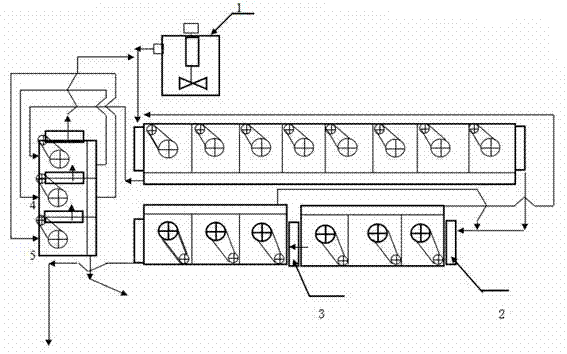

[0014] When in use, add this agent at 800g / ton of ore at the slurry mixing tank (1) (taking 6% antimony in gold concentrate as an example, it can be increased or decreased according to the amount of antimony), and in sweeping one (2), fine ore Add this agent at 100g / ton of ore, 240g / ton of ore, and 300g / ton of ore at election one (4) and selection two (5). The reaction time is 1-3 minutes after adding this agent in each section. Other operations are the same as conventional flotation.

Embodiment 2

[0016] The difference from Example 1 is that potassium sodium sulfite and potassium humate are used to replace sodium sulfite and sodium humate respectively.

Embodiment 3

[0018] The difference from Example 1 is that sodium sulfite, sodium humate and potassium permanganate are dissolved in water at a mass ratio of 40:30:30.

[0019] The flotation agent of the present invention has an inhibitory effect on pyrite and arsenopyrite as gold carriers in the gold concentrate after the gold ore associated with gold and antimony is enriched by flotation, and the inhibitory effect on stibnite Weaker, it can significantly increase the difference in floatability between stibnite, pyrite and arsenopyrite. Compared with traditional flotation, the agent of the present invention can increase the separation effect of gold and antimony by more than 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com