Novel rapid connection type detachable filter flask installation component

An installation component and quick-connect technology, which is applied in the field of filter bottles in the field of water treatment technology, can solve the problems of troublesome disassembly, water leakage, inconvenient replacement of filter elements, etc., and achieves the effect of convenient disassembly and assembly, simple assembly structure, and avoiding troublesome disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

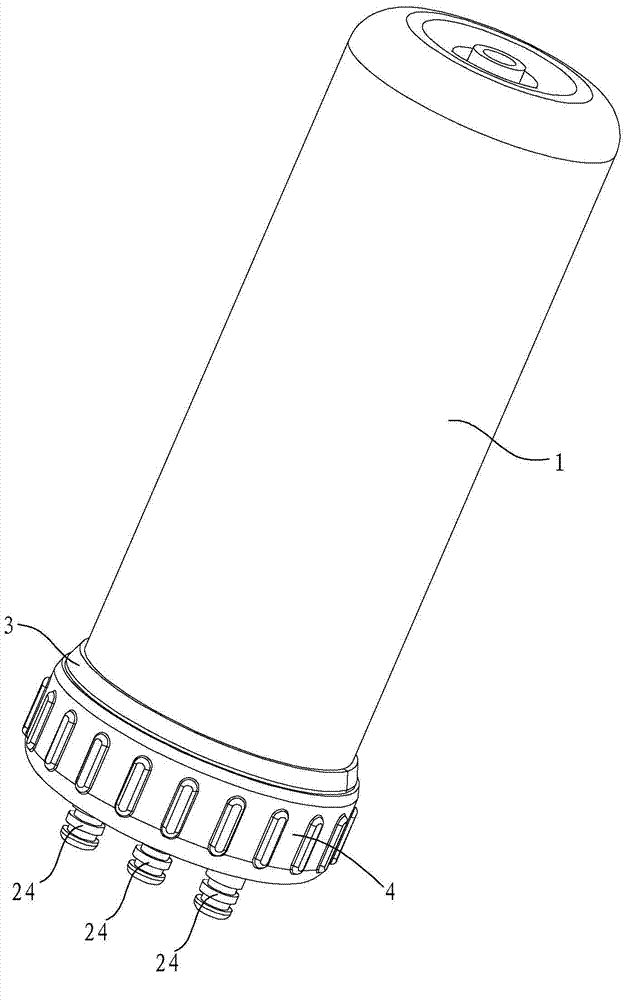

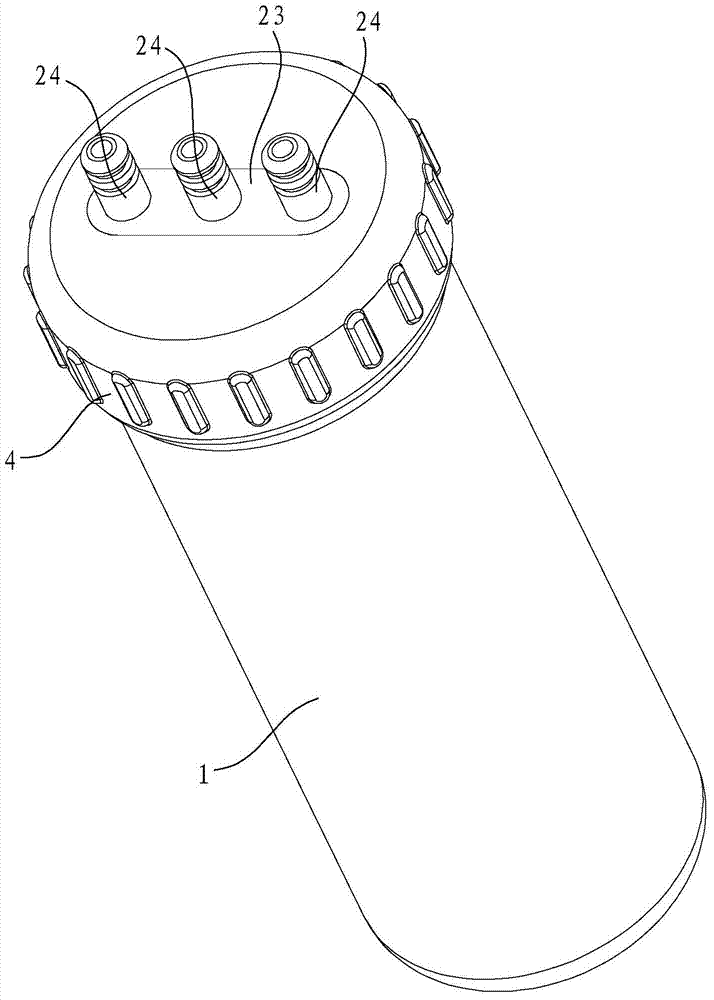

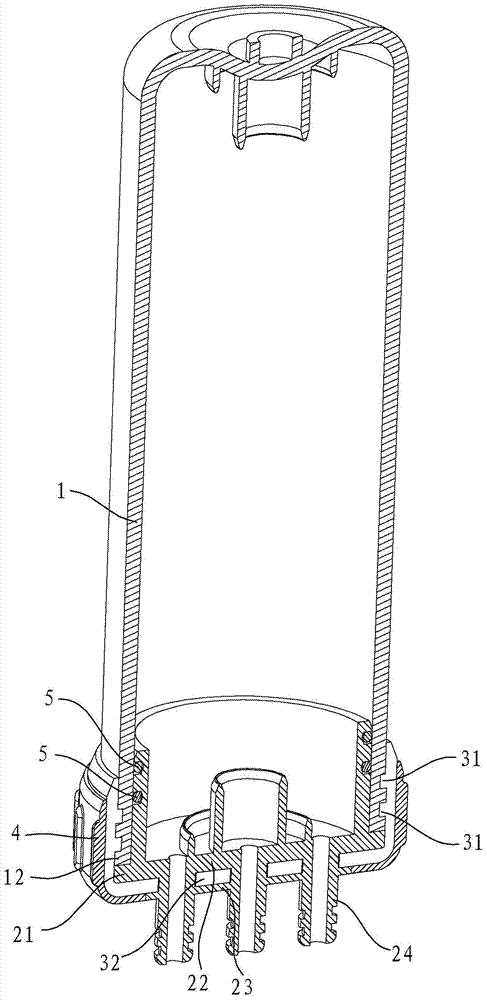

[0022] Such as Figure 1 to Figure 6 As shown, the new quick-connect detachable filter bottle installation assembly in this embodiment includes a bottle body 1 , a bottle stopper 2 , an insert 3 , a bottle cap 4 and a sealing ring 5 . Wherein, the bottle stopper 2 is used as a sealing connection frame, and the bottle stopper 2 is plugged into the opening end of the bottle body 1 and is sealed with the inner wall of the bottle body opening end. In this embodiment, both the opening end of the bottle body 1 and the bottle stopper 2 are round mouths, the upper end of the bottle stopper 2 extends into the opening end of the bottle body, and the outer peripheral wall of the upper end of the bottle stopper 2 is provided along the circumferential direction. Two annular grooves 25, and the two annular grooves 25 are arranged in parallel at intervals f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com