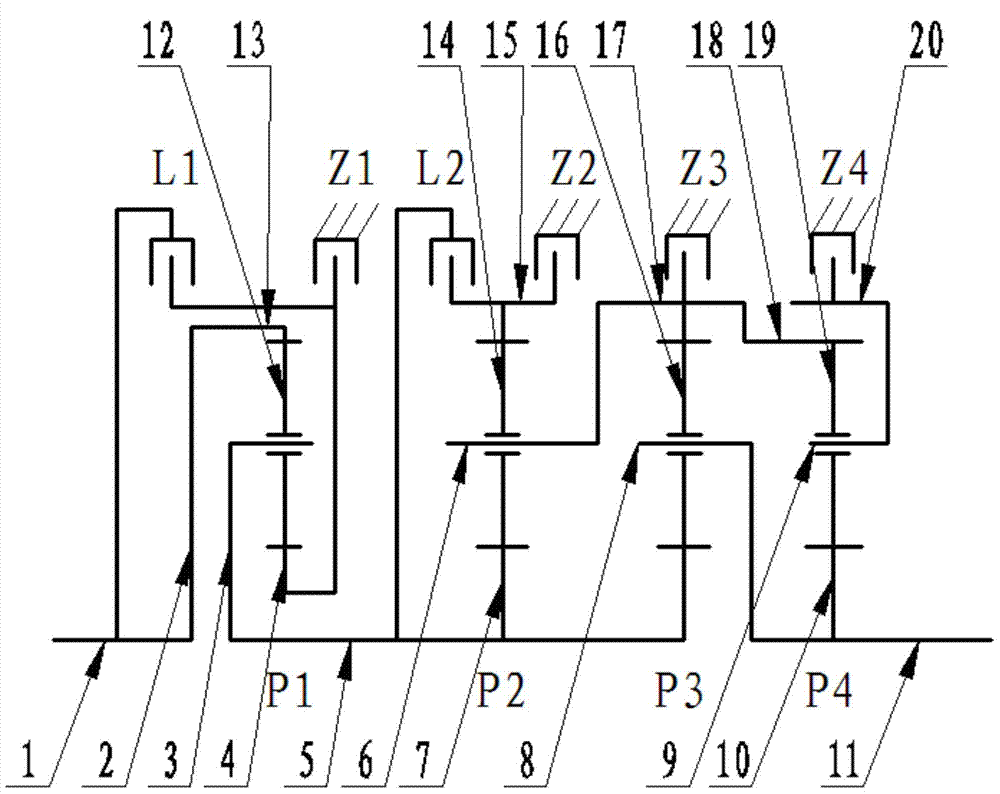

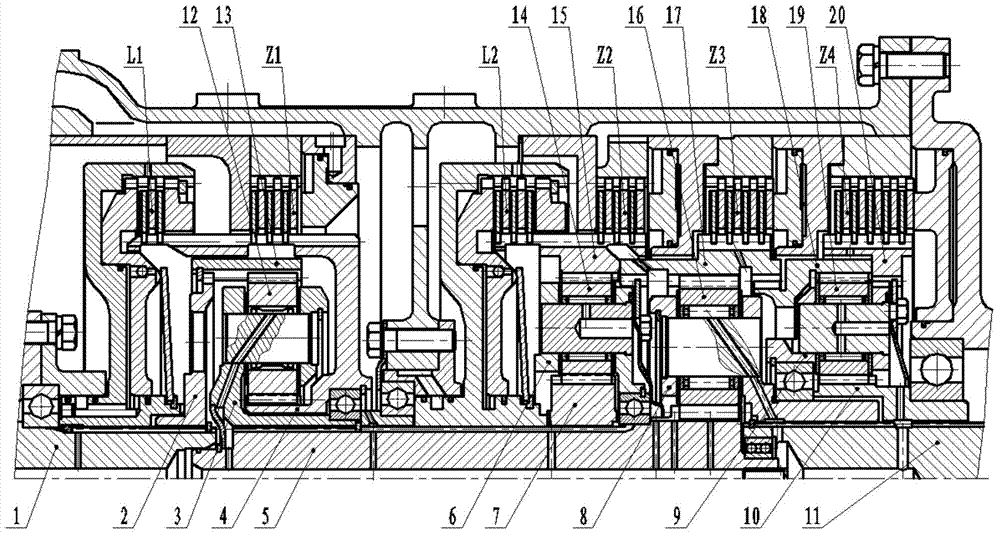

Drive mechanism of hydrodynamic transmission

A hydraulic transmission and transmission mechanism technology, applied in the direction of transmission components, transmission devices, vehicle gearboxes, etc., can solve the problems of large phase difference, unstable work, shifting shock, etc., and achieve a large transmission ratio range, reasonable structure, and set uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] First gear, when the first brake Z1 and the fourth brake Z4 are combined, the first sun gear 4 and the fourth planet carrier 9 are braked, and the input shaft 1 drives the first planet through the first ring gear case 2 and the first ring gear 13 The frame 3 rotates in the same direction, and the third sun gear shaft 5 connected to the first planet carrier 3 also rotates at the same speed, and the third sun gear shaft 5 drives the third planet carrier 8 and the fourth sun gear 10 to Rotating in the same direction, the output shaft 11 connected to the third planet carrier 8 and the fourth sun gear 10 also rotates at the same rotational speed. At this time, the speed ratio of the planetary gear transmission mechanism is i1=(1+α1) / α1*(1+α3+α3 / α4), and the second planetary row P2 is in an idling state and does not participate in power transmission. Wherein α1 is the structural parameter of the first planetary row P1, α3 is the structural parameter of the third planetary row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com