Firm and durable gear for hub motor of electric vehicle

A technology for hub motors and electric vehicles, applied in gear transmissions, belts/chains/gears, mechanical equipment, etc., can solve driver safety hazards, loose gears, gear wear and other problems, reduce wear and improve tightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

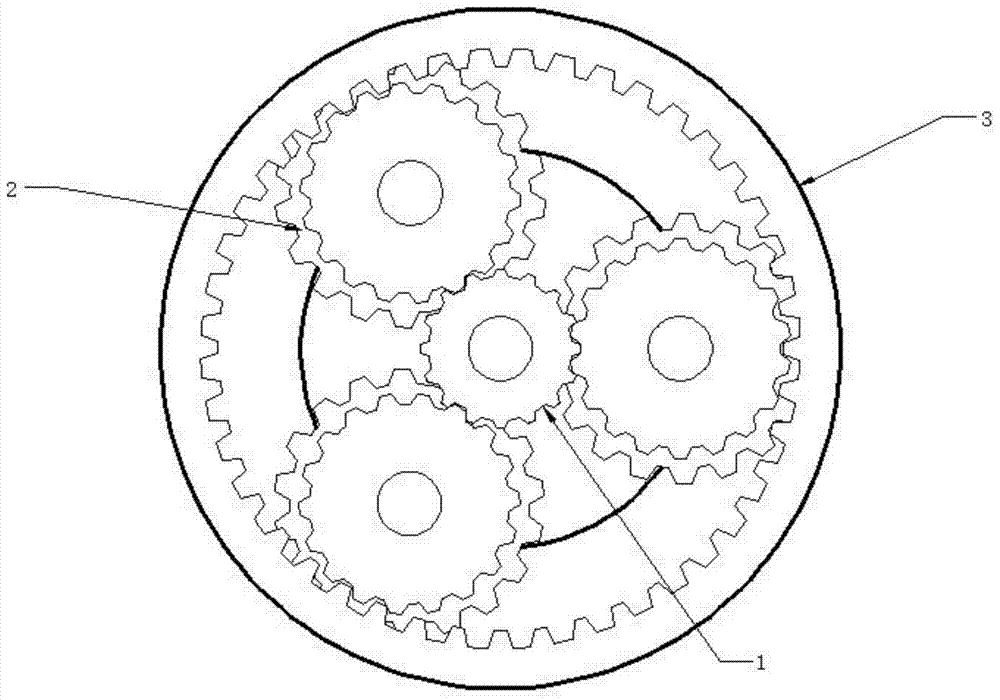

[0013] Such as figure 1 As shown, the electric wheel hub motor gear is composed of a sun gear 1, a planetary gear 2 and an outer ring gear 3. The sun gear 1 is installed on the top of a mandrel, and when the mandrel rotates, the sun gear 1 will also rotate accordingly. With the sun gear 1 as the center, it meshes with three planetary gears 2, and the angles between the three planetary gears 2 are 120 degrees. There is an annular outer ring gear 3 outside the three planetary gears 2 , and the outer ring gear 3 meshes with the three planetary gears 2 at the same time.

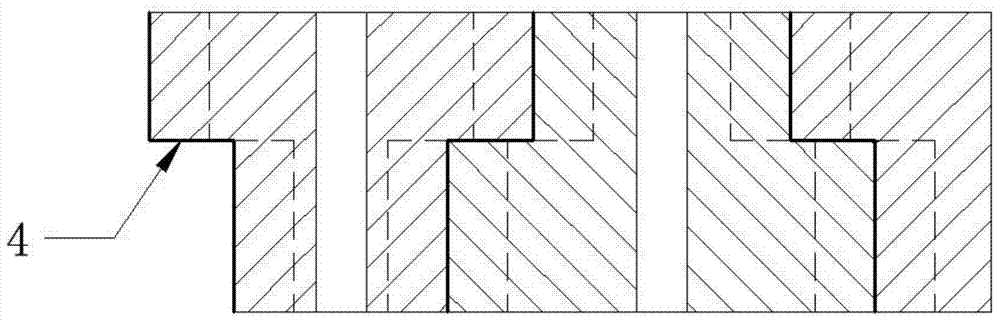

[0014] On the sun gear 1, there is a sun gear boss 11, and the sun gear boss 11 is provided with teeth of different specifications on the sun gear 1. And the planet gear 2 meshed with the sun gear 1 also has a planet boss 21 , and the teeth provided on the planet boss 21 mesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com