A three-way shock-absorbing mass-tuned damper

A shock-absorbing mass and damper technology, which is applied in the direction of shockproof, bridge parts, building components, etc., can solve the problems of incomplete quality requirements in the two directions, troublesome design, complicated installation, etc., and achieves wide applicability, simple design, Ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

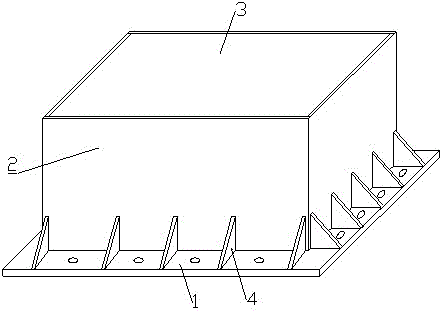

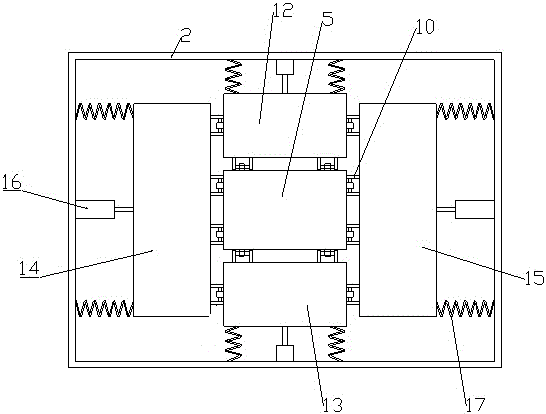

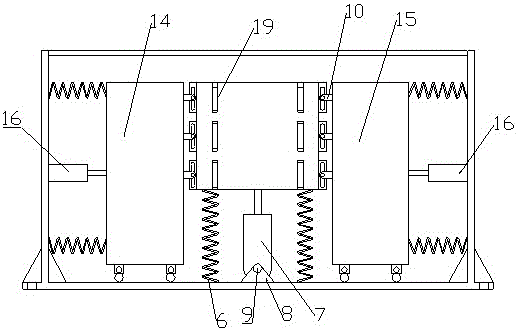

[0022] Such as figure 1 , 2 , 3, 4, 5, and 6, a three-way shock-absorbing mass tuned damper, including a base 1, a steel cylinder 2 fixedly installed on the base 1, a sealing plate 3 installed on the top of the steel cylinder 2, the A horizontal damping device is arranged inside the steel cylinder 2, and the horizontal damping device is connected with the inner wall of the steel cylinder 2 through a horizontal viscous damper 16 and a horizontal spring 17, and a vertical mass is arranged at the center of the horizontal damping device. Block 5, the bottom of the vertical mass block 5 is connected to the base 1 through a vertical viscous damper 7 and a vertical spring 6, and a directional rotation shaft support 8 is arranged between the base 1 and the vertical viscous damper 7, and the directional rotation shaft The support 8 is connected to the vertical viscous damper 7 via an orientation rotation axis 9 .

[0023] Described horizontal damping device comprises first horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com