Manufacturing method of corundum crucible for vacuum induction melting superalloy

A vacuum induction melting and high-temperature alloy technology, which is applied in the field of metallurgy, can solve the problems of poor high-temperature chemical stability of pure corundum, cannot be used as a high-temperature alloy, and poor thermal shock stability. Good thermal shock resistance at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

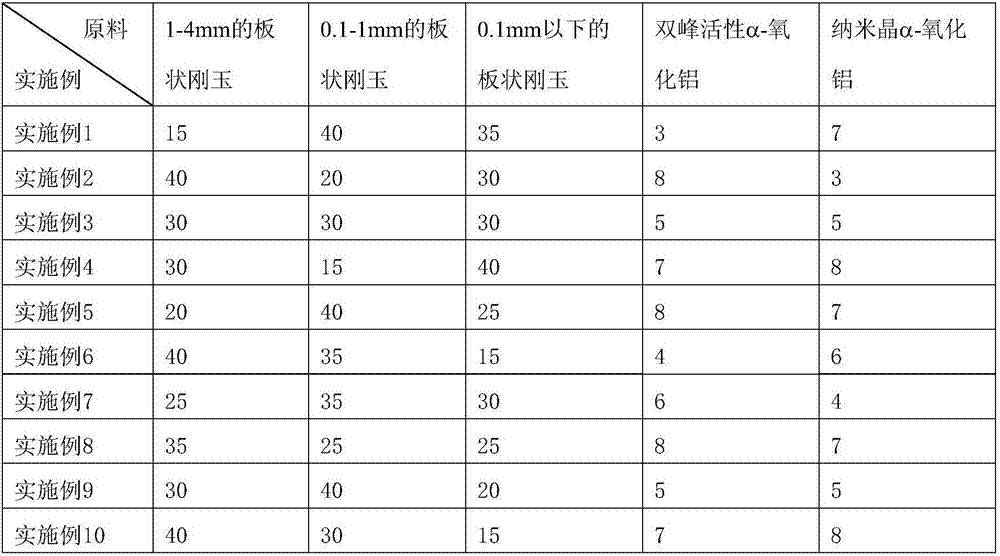

[0016] Embodiment 1, the manufacture of corundum crucible for vacuum induction melting superalloy, comprises the following steps:

[0017] 1) After weighing according to the ratio in Table 1, mix it with a dispersant and a binder to obtain a uniform alumina slurry. The dispersant used is ammonium polyacrylate, and the amount added is 0.5% of the total mass of alumina raw materials. The binder is propylene The mixed aqueous solution of amide and N,N'-methylenebisacrylamide, the mass ratio of the two is 10:1, the total mass percentage concentration of the mixed aqueous solution is 14%, and the amount of binder added is the total mass of alumina raw materials 5% of

[0018] 2) Add an initiator to the alumina slurry obtained in step 1), mix at 30°C for 3 minutes, the initiator is 2,2'-azo hydrochloride, and the amount added is 0.3% of the total mass of the alumina slurry;

[0019] 3) The alumina slurry obtained in step 2) was vacuum degassed at 30° C. for 5 minutes, and immediate...

Embodiment 2

[0022] Embodiment 2, the manufacture of a corundum crucible for vacuum induction melting superalloys comprises the following steps:

[0023] 1) After weighing according to the ratio in Table 1, mix it with a dispersant and a binder to obtain a uniform alumina slurry. The dispersant used is ammonium polyacrylate, and the amount added is 1.5% of the total mass of the alumina raw material. The binder is propylene The mixed aqueous solution of amide and N,N'-methylenebisacrylamide, the mass ratio of the two is 10:1, the total mass percentage concentration of the mixed aqueous solution is 14%, and the amount of binder added is the total mass of alumina raw materials 10% of;

[0024] 2) Add an initiator to the alumina slurry obtained in step 1), and mix at 30°C for 6 minutes. The initiator is piperidine hydrochloride, and the amount added is 0.2% of the total mass of the alumina slurry;

[0025] 3) The alumina slurry obtained in step 2) was vacuum degassed at 30° C. for 5 minutes, ...

Embodiment 3

[0028] Embodiment 3, the manufacture of corundum crucible for vacuum induction melting superalloy comprises the following steps:

[0029] 1) After weighing according to the ratio in Table 1, mix it with a dispersant and a binder to obtain a uniform alumina slurry. The dispersant used is ammonium polyacrylate, and the amount added is 2% of the total mass of the alumina raw material. The binder is propylene The mixed aqueous solution of amide and N,N'-methylenebisacrylamide, the mass ratio of the two is 10:1, the total mass percentage concentration of the mixed aqueous solution is 14%, and the amount of binder added is the total mass of alumina raw materials 15% of;

[0030] 2) Add an initiator to the alumina slurry obtained in step 1), mix at 30°C for 8 minutes, the initiator is 2,2'-azo hydrochloride, and the amount added is 0.15% of the total mass of the alumina slurry;

[0031] 3) The alumina slurry obtained in step 2) was vacuum degassed at 30° C. for 5 minutes, and immedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com