High-strength gypsum retarder and preparation method thereof

A high-strength gypsum and retarder technology, which is applied in the field of high-strength gypsum retarders, can solve the problems that retarders have little research on the hydration process of gypsum, and achieve low cost, high-efficiency retarder effect, and enhanced retarder effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

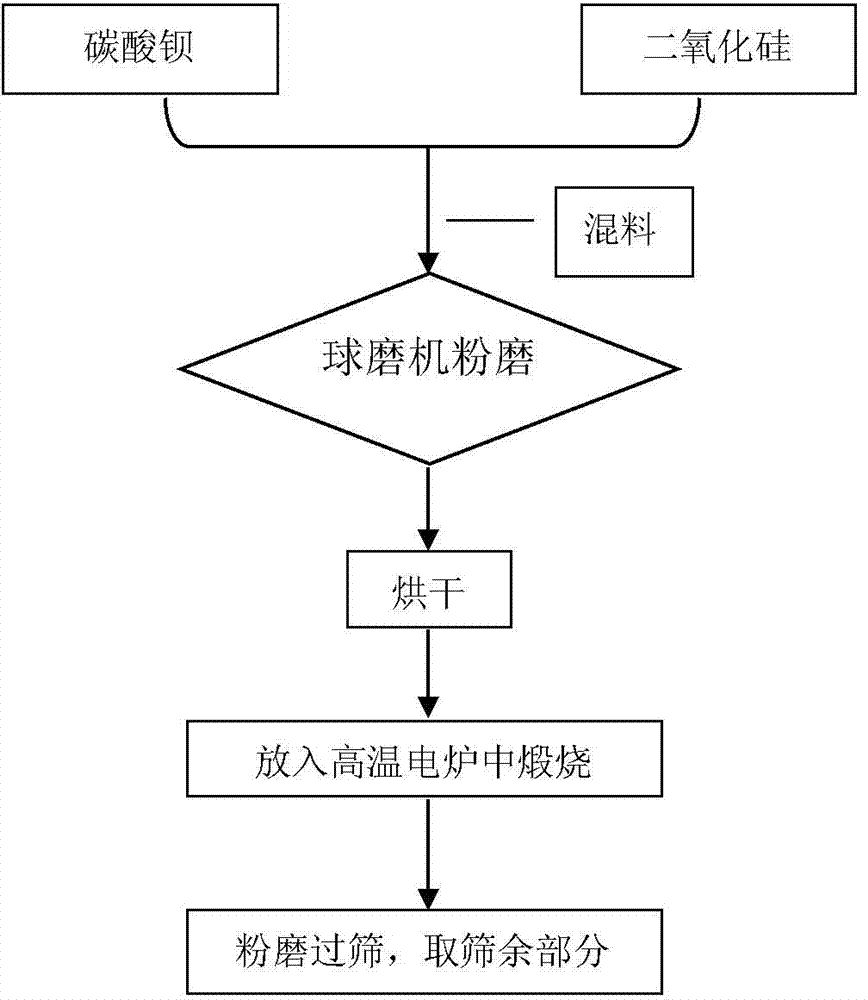

[0022] The specific implementation steps are attached figure 1 As shown, weigh 338g of barium carbonate and 87.41g of silicon dioxide at a molar ratio of 2:1, mix them evenly, put them into a ball mill to grind them for 1 hour, dry them in an oven at (45±5)°C, and put them into a high-temperature electric furnace at 1200°C Internally calcined for 3 hours, took out and sieved to obtain 200g of dibarium silicate retarder. Different dosages of retarders were selected, and the setting time and strength properties were tested under the standard consistency of water consumption. At the same time, the high-strength gypsum without retarder was used as a comparison.

[0023]

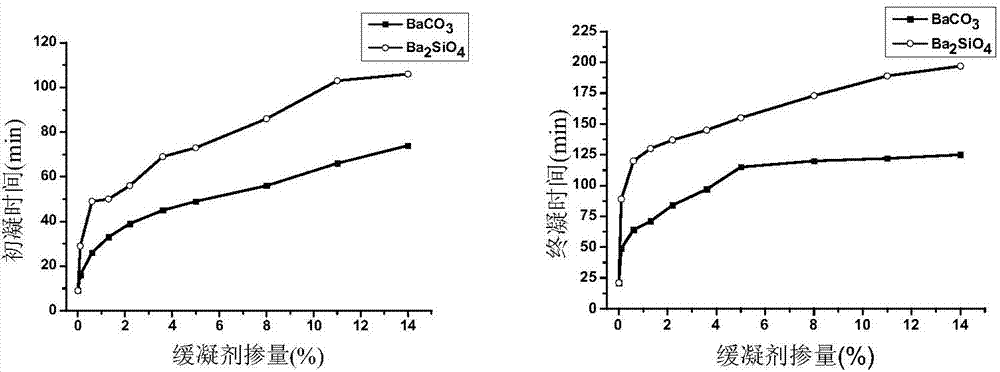

[0024] as attached figure 2 As shown, it can be seen that the setting time increases with the increase of retarder content, but the change of setting time is no longer obvious after 8%. After adding a single dibarium silicate retarder, the strength loss of gypsum is smaller than that of a single barium carb...

Embodiment 2

[0026] Select 8% retarder as a benchmark, adjust the weight ratio of barium carbonate and dibarium silicate, and compare the setting time and strength performance test:

[0027]

[0028]

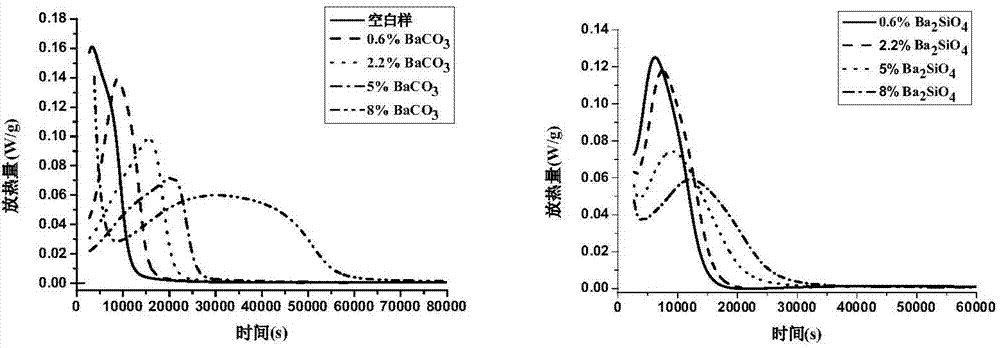

[0029] Adding dibarium silicate to a retarder with a large specificity has a small strength loss and a long retarding time. attached by image 3 It can be seen that the exothermic heat of dibarium silicate at the same dosage is smaller than that of barium silicate, so it has a better retarding effect.

[0030] It can be seen from the above examples that the retarder can effectively prolong the setting time of high-strength gypsum, and the strength loss of hardened gypsum is small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com