Modular rubber plate for roller rubber coating

A modularized, roller-packed technology, applied in the direction of transportation and packaging, conveyor objects, rollers, etc., can solve the problems of rubber sheet falling off, waste, and increase costs, so as to facilitate the construction of rubber wrapping, reduce spare parts inventory, and eliminate waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

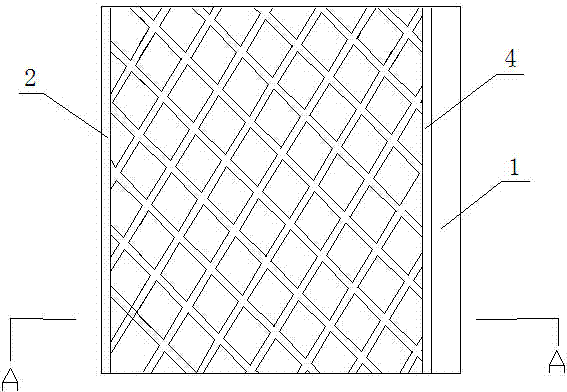

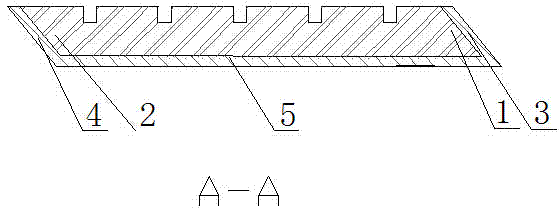

[0024] Such as figure 1 , 2 As shown, a modular rubber sheet used for drum lagging, the rubber sheet head 1 and the rubber sheet tail 2 are respectively provided with socket joints, and the length of the rubber sheet working surface between the head and the tail is 157±20mm. The socket joint 3 at the head of the rubber sheet is wedge-shaped, and the socket joint 4 at the tail of the rubber sheet is a reverse wedge shape matched with the head. The adhesive surface of the rubber plate is provided with a soft rubber layer 5, and the width of the rubber plate is 300 mm. The thickness of the rubber sheet is 8mm.

[0025]

Embodiment 2

[0027] Such as figure 1 , 3 As shown, a modular rubber sheet used for drum lagging, the rubber sheet head 1 and the rubber sheet tail 2 are respectively provided with socket joints, and the length of the rubber sheet working surface between the head and the tail is 314±20mm. The socket joint 3 at the head of the rubber sheet is stepped, and the socket joint 4 at the end of the rubber sheet is in the shape of a reverse step matched with the head. The adhesive surface of the rubber plate is provided with a soft rubber layer 5 . The width of the rubber sheet is 500mm. The thickness of the rubber sheet is 9mm.

Embodiment 3

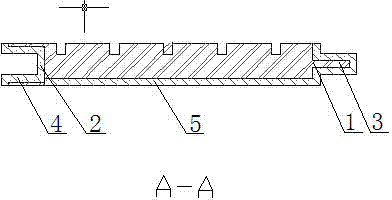

[0029] Such as figure 1 , 4 As shown, a modular rubber sheet used for drum lagging, with socket joints at both ends of the rubber sheet head 1 and rubber sheet tail 2, and the length of the working surface of the rubber sheet between the head and the tail is 471±20mm. The socket joint 3 at the head of the rubber sheet is convex, and the socket joint 4 at the tail of the rubber sheet is concave to match the head. The adhesive surface of the rubber plate is provided with a soft rubber layer 5 . The width of the rubber sheet is 1000mm. The thickness of the rubber sheet is 10mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com