Machining device for V-shaped mark of motor cover cap

A processing device and motor cover technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of easy operator fatigue, improper operation, easy knocking on the hand, etc., to improve working conditions, labor The effect of strength reduction and less fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

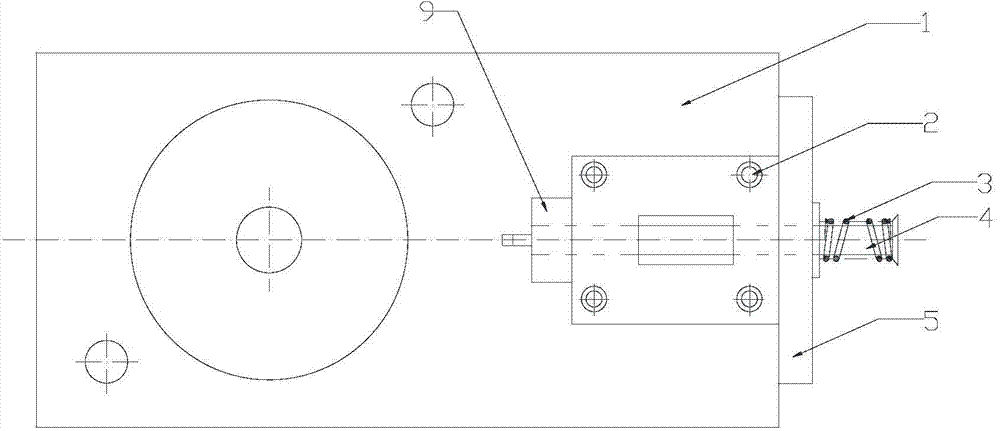

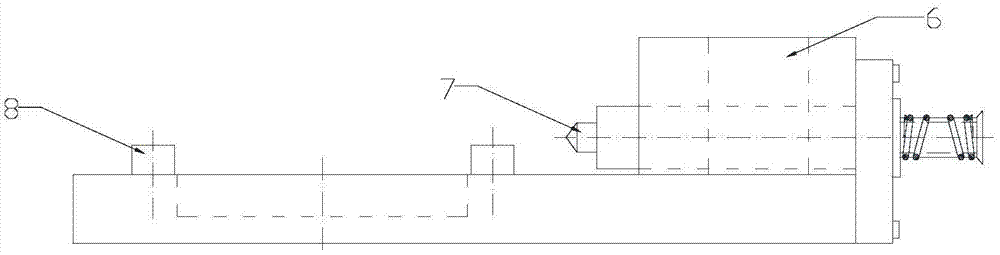

[0024] Such as Figure 1-Figure 2 As shown, a processing device for the V-shaped mark of the motor cover, including a workpiece fixing part and an impact assembly. The workpiece fixture includes a base plate 1 and a positioning pin 8 arranged on the base plate 1, the base plate 1 is provided with a groove for placing the workpiece, the groove matches the outer diameter of the workpiece, and the positioning pin 8 is set There are multiple, matched with the holes on the workpiece, used to limit the rotation of the workpiece. The material of the bottom plate 1 can be selected from 45#,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com