Hydraulic systems especially for actuating drive trains

A technology of hydraulic system and transmission system, applied in the field of hydraulic system, can solve the problems of driving off module actuation and cooling loss too much energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

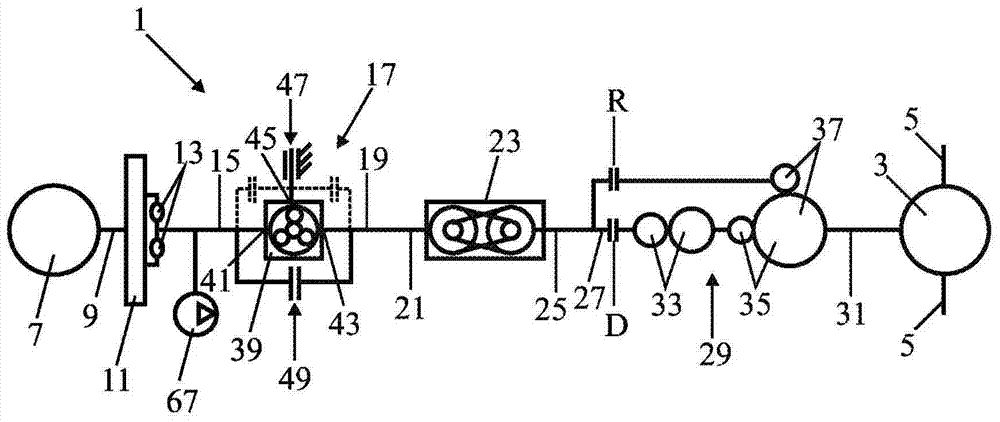

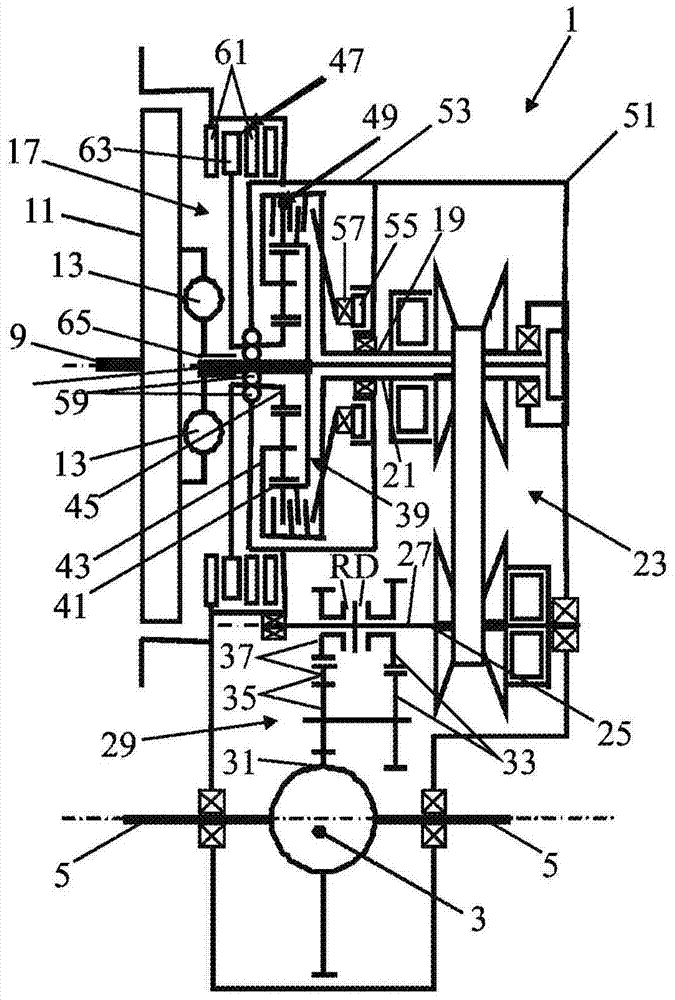

[0051] figure 1 The layout of a drive mechanism equipped with a hydraulic system according to the invention is shown. The drive mechanism 1 is provided in a vehicle, of which only a differential 3 and a drive shaft 5 connected to the wheels are shown. The driving mechanism includes a driving source 7, which is constituted by an internal combustion engine in this embodiment, but may also be constituted by, for example, an electric motor. A flywheel 11 is located on the output shaft 9 of the drive source, the flywheel is connected to the input part 15 of the drive-off module 17 via a torque damper 13 . The output 19 of the drive-off module is connected to an input shaft 21 of a transmission forming part of the drive mechanism. In this embodiment, the transmission is constituted by a CVT transmission 23 in which the output shaft 25 is connected to the input 27 of a final drive 29 forming part of the drive train. The output 31 of the final drive is connected to the differential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com