Device for SMT process and control method of device

A technology of process equipment and control method, applied in the direction of electrical components, electrical components, etc., can solve the problems of mixing materials, waste of production capacity of reflow furnace, increase of manpower input, etc., to overcome production bottlenecks, stabilize heat absorption, and avoid over-dense arrangement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

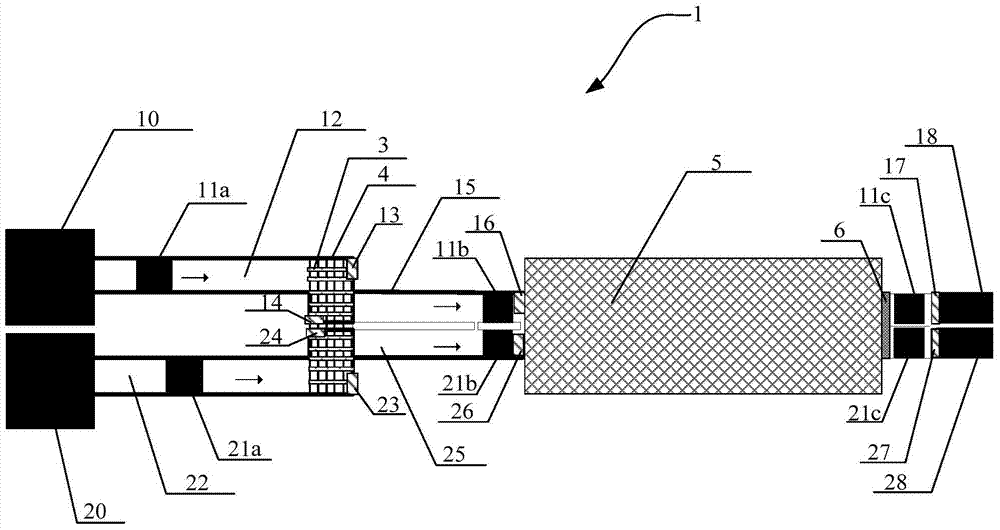

[0026] Such as figure 1 As shown, as a preferred embodiment of the present invention, a device 1 for the SMT process includes: a first placement machine 10, which performs placement processing on the first product 11a, 11b, 11c; the second placement machine 20. Carry out patch processing on the second product 21a, 21b, 21c; reflow furnace 5, perform reflow processing on the first product 11a, 11b, 11c and the second product 21a, 21b, 21c; and connect all The first placement machine 10 and the first guide rails 12, 15 of the reflow furnace 5 (it should be noted that the guide rail refers to the entire device for transporting products, not just the conveyor belt that is in contact with the product surface.); The second placement ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com