Manufacturing method of high-precision wallboard mould

A manufacturing method and high-precision technology, applied in the field of mold manufacturing, can solve problems such as poor accuracy, waste of manpower and material resources, and inability to comprehensively optimize parameters, etc., to achieve the effects of prolonging service life, meeting manufacturing needs, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

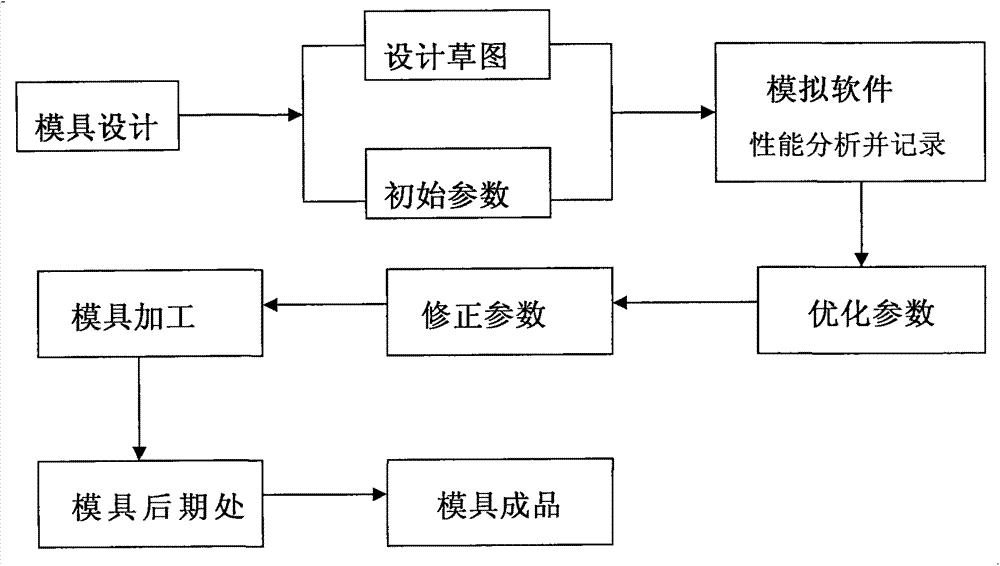

[0011] A method for manufacturing a high-precision wallboard mould, the steps of which include (1) mold design, drawing the mold structure prototype by computer and determining the parameters required for mold manufacturing; (2) mold precision analysis and optimization, using computer simulation software to simulate the mold Carry out simulation calculations for each parameter, record and analyze the comprehensive performance of the mold, find out the parameters of the best comprehensive performance of the mold, modify and correct the parameters that do not meet the standards, and finally determine the mold processing parameters; (3) mold processing and Post-processing, the initial processing of the mold is carried out according to the mold processing parameters. After the initial processing is completed, the surface gloss is processed to correct the molding error and make it within the standard range. Wherein the comprehensive performance of the mold in step (2) includes struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com