Security construction method for sealing expansion joint of airport runway take-off and landing strip

A technology of lifting belts and airports, applied in the direction of roads, roads, pavement details, etc., to achieve the effect of solving economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

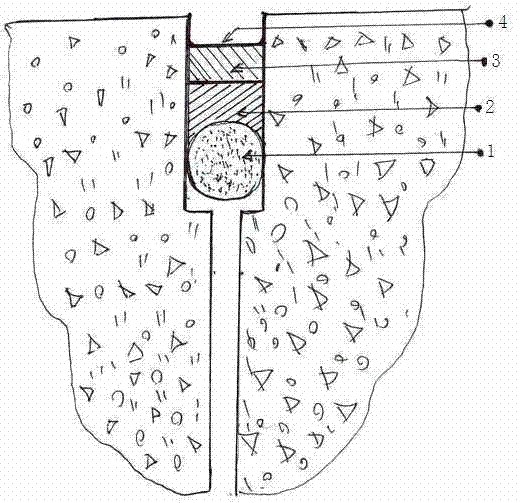

[0013] A maintenance construction method for the sealing of the expansion joints of the runway lifting belt of the airport, comprising the following steps: firstly remove the sealant that has lost the waterproof effect in the expansion joints 4 of the lifting belt of the airport runway, and use a repair vehicle to remove the sealing glue of the expansion joints 4 of the lifting belt of the airport runway. Grind the side walls on both sides to ensure that the original sealant is completely removed, and then use a hair dryer to blow off the dust on both side walls of the runway lift belt expansion joint 4, and then insert foam with a diameter 2mm wider than the airport runway lift belt expansion joint Sealing strip 1, insert 5mm thick silicone sealant 2 on top of the foam sealing strip 1, cure for 7 days until the silicone sealant 2 initially solidifies, and then insert 4mm thick polyurethane sealant 3, so far all the work is completed.

Embodiment 2

[0015] A maintenance construction method for the sealing of the expansion joints of the runway lifting belt of the airport, comprising the following steps: firstly remove the sealant that has lost the waterproof effect in the expansion joints 4 of the lifting belt of the airport runway, and use a repair vehicle to remove the sealing glue of the expansion joints 4 of the lifting belt of the airport runway. Grind the side walls on both sides to ensure that the original sealant is completely removed, and then use a hair dryer to blow off the dust on both side walls of the runway lift belt expansion joint 4, and then insert foam with a diameter 1mm wider than the airport runway lift belt expansion joint Sealing strip 1, insert 4mm thick polysulfide sealant 2 on top of foam sealing strip 1, cure for 1 day until the polysulfide sealant 2 is initially solidified, and then insert 2mm thick polyurethane sealant 3, so far all the work is completed.

Embodiment 3

[0017] A maintenance construction method for the sealing of the expansion joints of the runway lifting belt of the airport, comprising the following steps: firstly remove the sealant that has lost the waterproof effect in the expansion joints 4 of the lifting belt of the airport runway, and use a repair vehicle to remove the sealing glue of the expansion joints 4 of the lifting belt of the airport runway. Grind the side walls on both sides to ensure that the original sealant is completely removed, and then use a hair dryer to blow off the dust on both side walls of the runway lift belt expansion joint 4, and then insert foam with a diameter 2mm wider than the airport runway lift belt expansion joint Sealing strip 1, insert 10mm thick polysulfide sealant 2 above the foam sealing strip 1, cure for 5 days until the polysulfide sealant 2 is initially solidified, and then insert 6mm thick polyurethane sealant 3, so far all the work is completed.

[0018] The core steps of the pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap