Vehicle Pneumatic Tires

A technology for pneumatic tires and vehicles, applied in vehicle parts, tire parts, tire treads/tread patterns, etc., can solve problems such as hindering water-skid performance, and achieve the effects of good water-skid performance and high lateral rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

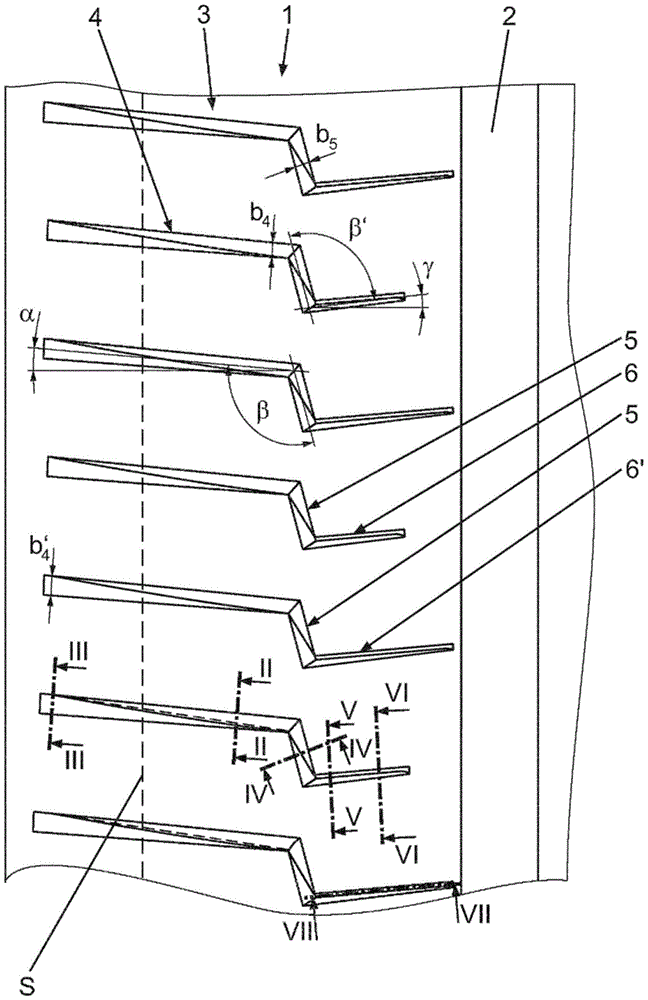

[0020] figure 1 A plan view shows a circumferential section of a tread strip 1 running on the shoulder side of a tread of a pneumatic vehicle tire, in particular a tire for passenger cars. The tread of a pneumatic tire for vehicles is generally composed of a plurality of lugs, which are separated from one another by circumferential grooves and which are implemented as tread strips, blocks rows or the like.

[0021] exist figure 1 The tread band 1 shown in is a tread band extending on the shoulder side of the tread through a figure 1 The circumferential grooves 2 shown in , which run around in the circumferential direction of the tread, are separated from a further structured tread region, which is not shown in detail. The dotted line S generally symbolizes the outer limit of the tread-ground contact area located in the tread band 1 and produced during tire operation.

[0022] The shoulder-side tread band 1 is provided on its circumference with a plurality of transverse groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com