Remote training, fault diagnosis system of production system and implementation method thereof

A fault diagnosis system and production system technology, applied in general control system, control/adjustment system, program control, etc., can solve the problems of not being able to fully utilize the advantages of the coal mine comprehensive automation system, problems that cannot be found in time, and skills and technologies that are not high , to achieve the effect of improving operating efficiency, increasing the number of controlled devices, and powerfully expanding functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

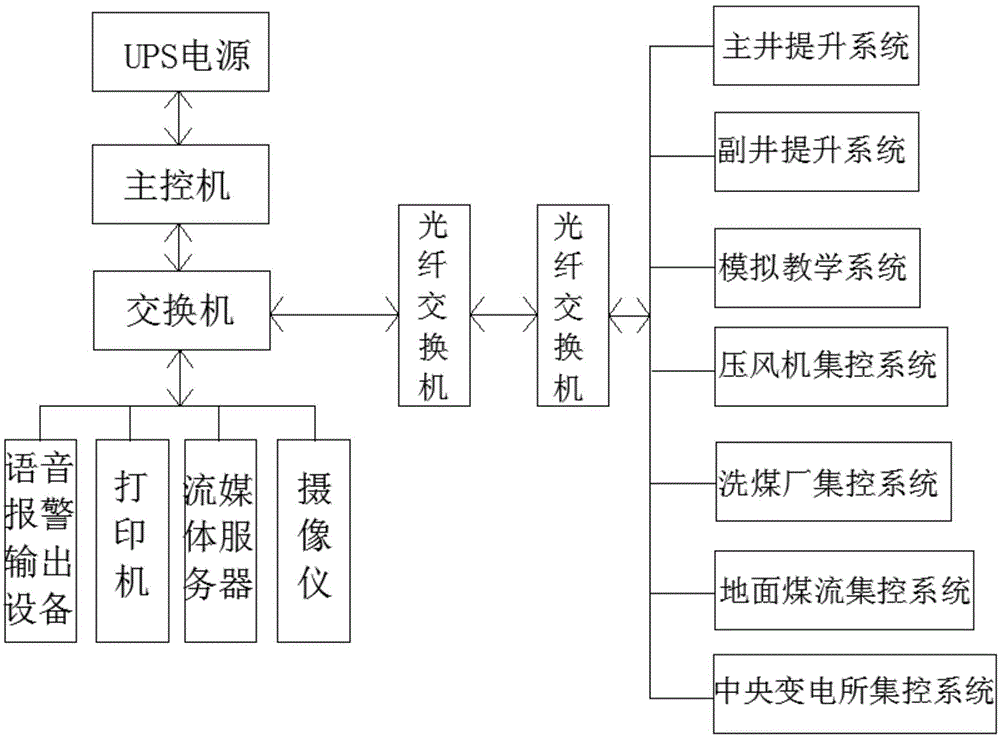

[0019] like figure 1 As shown, a remote training and fault diagnosis system for a production system includes a main control computer installed on the well, a switch connected to the main control computer, a voice alarm output device connected to the switch, a printer, a streaming media server, a camera instrument; the switch is respectively connected to the main shaft hoisting system, the centralized control system of the central substation, the centralized control system of the compressor, the centralized control system of the surface coal flow, the centralized control system of the coal washing plant, and the simulation teaching system through a pair of optical fiber switches. The optical fiber switches are connected through optical cables.

[0020] It also includes a UPS power supply, and the UPS power supply is connected with the main control machine.

[0021] It also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com