Overall Calibration Method of Measurement System in Transformer Test Station

A technology of measurement system and calibration method, applied in measurement devices, measurement of electrical variables, instruments, etc., can solve the problems of inability to display errors, slow speed, inability to calibrate measurement systems, etc., and achieve accurate comprehensive error, measurement comprehensive error, calibration Test the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

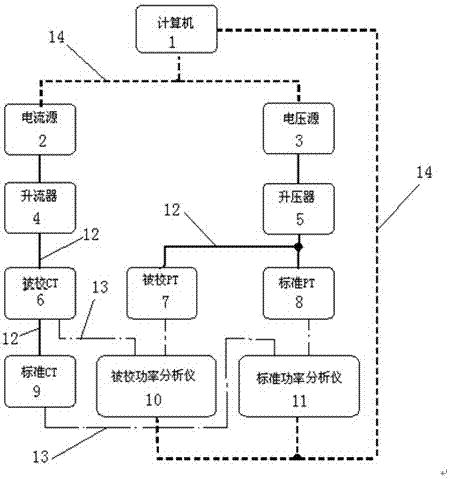

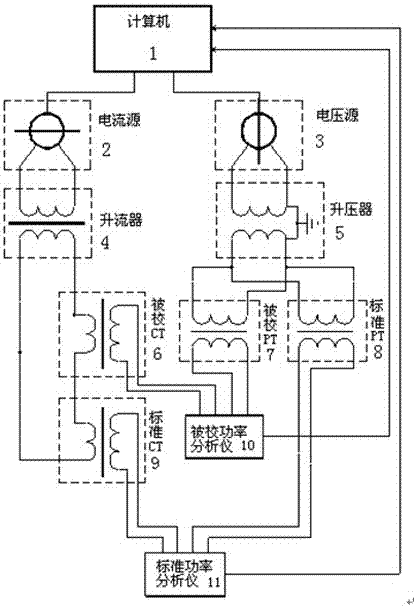

[0016] refer to Figure 1-Figure 2 , an overall calibration method for a transformer test station measurement system, including a computer 1, a current source 2, a voltage source 3, a current booster 4, a booster 5, a calibrated CT6, a calibrated PT7, a standard PT8, a standard CT9, a calibrated Power analyzer 10 and standard power analyzer 11. The computer 1 is connected to one end of the current source 2, the voltage source 3, the power analyzer 10 to be calibrated, and the power analyzer 11 to be calibrated, and the other end of the power analyzer 10 to be calibrated is respectively connected to the CT6 to be calibrated and the PT7 to be calibrated. The other end of the power analyzer 11 is connected to the standard CT9 and the standard PT8 respectively, the current source 2 is connected to the current booster 4, the CT6 to be calibrated and the standard CT9 in sequence, and the voltage source 3 is connected to the booster 5 in sequence, The booster 5 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com