High-precision measuring device and measuring method for volume change of irregular solid thermal expansion and contraction

A volume change, thermal expansion and contraction technology, applied in the field of physical experiments, can solve the problems of inability to measure the volume change, the accuracy cannot meet the requirements, and the measurement results are not obvious, etc., to achieve simple measurement steps, low price, and high detection accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

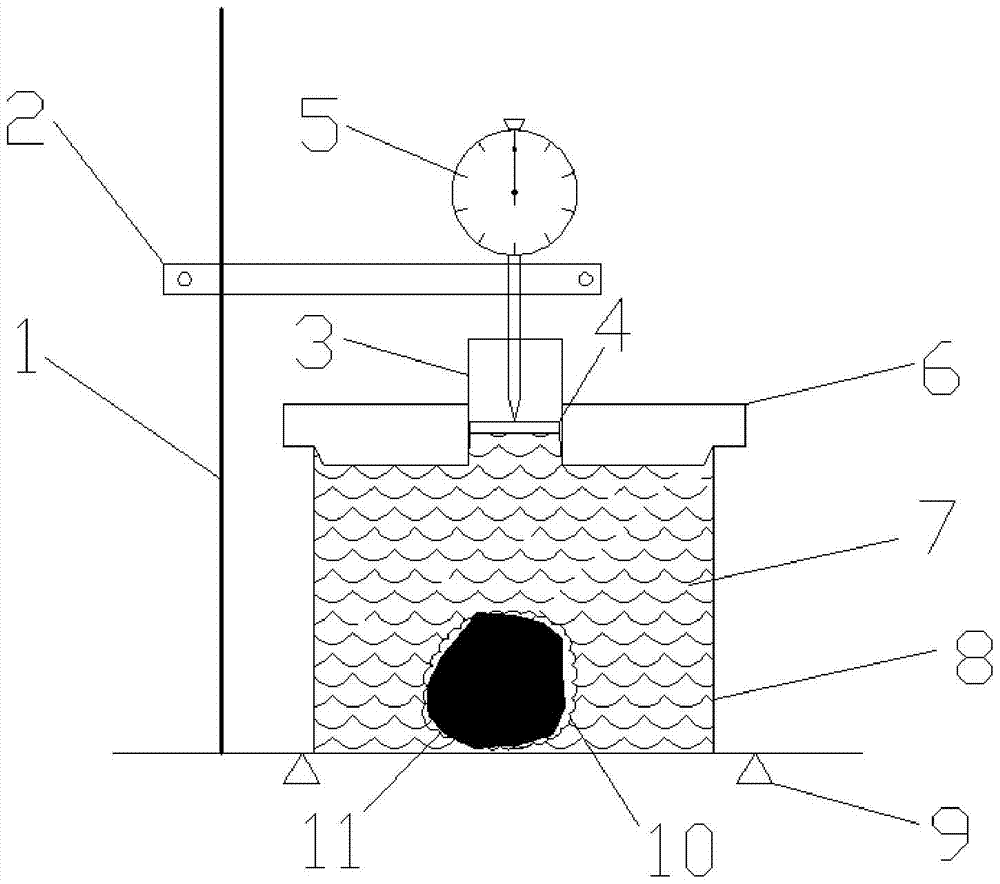

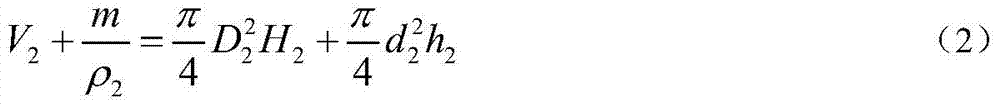

Embodiment 1

[0035] Embodiment 1: A vertical bar with a height of 350 mm, a square base with a side length of 250 mm, and a beam with a length of 200 mm are assembled into an iron stand; a circular shape with a wall thickness of 2 mm, an inner diameter of 150 mm, and a height of 150 mm is placed on the base of the iron stand. Glass cup; seal the solid sample with ultra-thin elastic rubber and put it into the glass cup, and plug the upper opening with a round rubber stopper with a thickness of 25mm; open a hole in the center of the round rubber stopper and insert it with a wall thickness of 1mm and an inner diameter of 1mm. 20mm, 55mm long glass round straight tube, and make its bottom flush with the lower end of the rubber stopper; inject a certain amount of pure water into the cavity formed by the glass cup and the rubber stopper, and keep it in the glass round straight tube A liquid column with a height of 35mm; place a circular foam sheet with a diameter slightly less than 20mm on the pu...

Embodiment 2

[0036] Embodiment 2: A vertical bar with a height of 400 mm, a square base with a side length of 300 mm, and a beam with a length of 220 mm are assembled into an iron stand; a circular shape with a wall thickness of 3 mm, an inner diameter of 260 mm, and a height of 300 mm is placed on the base of the iron stand. Glass cup; seal the solid sample with ultra-thin elastic rubber and put it into the glass cup, and plug the upper mouth with a 30mm thick round rubber stopper; open a hole in the center of the round rubber stopper and insert it with a wall thickness of 2mm, inner diameter 25mm, 70mm long glass round straight tube, and make the bottom end flush with the lower end of the rubber stopper; inject a certain amount of kerosene into the cavity formed by the glass cup and the rubber stopper, and keep 50mm in the glass round straight tube The height of the liquid column; place a circular foam sheet with a diameter slightly less than 25mm on the kerosene liquid surface; fix a dia...

Embodiment 3

[0037] Embodiment 3: Assemble a vertical bar with a height of 375mm, a square base with a side length of 275mm, and a beam with a length of 210mm to form an iron stand; place a circular shape with a wall thickness of 3mm, an inner diameter of 210mm, and a height of 250mm on the base of the iron stand. Glass cup; seal the solid sample with ultra-thin elastic rubber and put it into the glass cup, and plug the upper opening with a round rubber stopper with a thickness of 28mm; open a hole in the center of the round rubber stopper and insert it with a wall thickness of 2mm. 22mm, 60mm long glass round straight tube, and make the bottom end flush with the lower end surface of the rubber stopper; inject a certain amount of pure water into the cavity formed by the glass cup and the rubber stopper, and keep it in the glass round straight tube A liquid column with a height of 40mm; place a circular foam sheet with a diameter slightly less than 22mm on the pure water surface; fix a dial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com