A Misalignment Angle Calibration Method for Two-Dimensional Autocollimator

An autocollimator and calibration method technology, which is applied to instruments, measuring devices, etc., can solve the problems of limited calibration range, high cost, and difficulty in erection, and achieve the effects of large calibration range, flexible use, and convenient erection and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

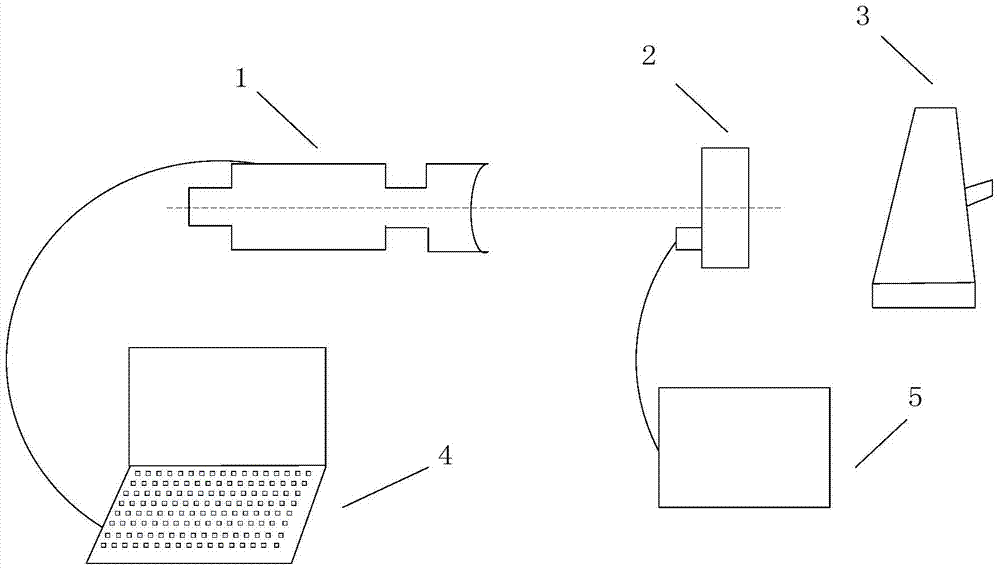

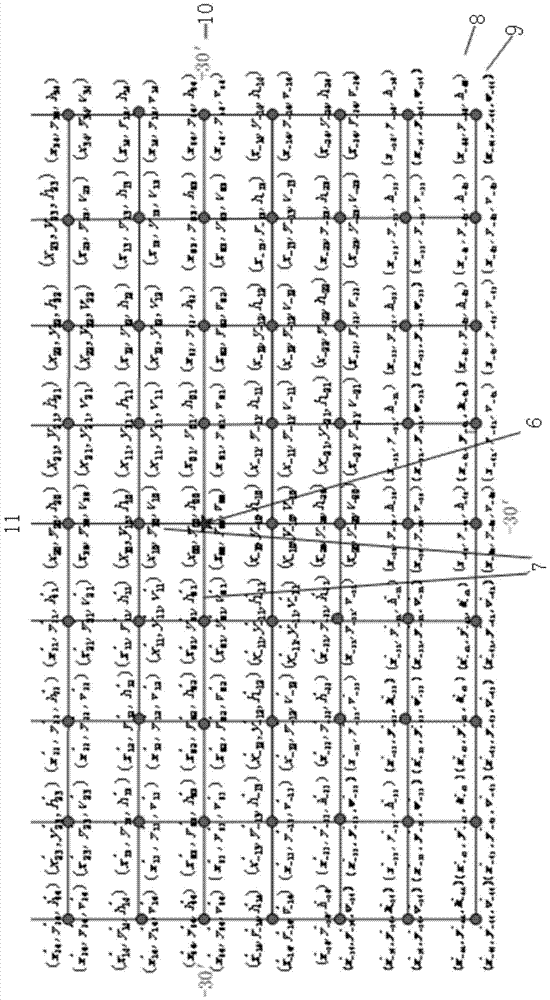

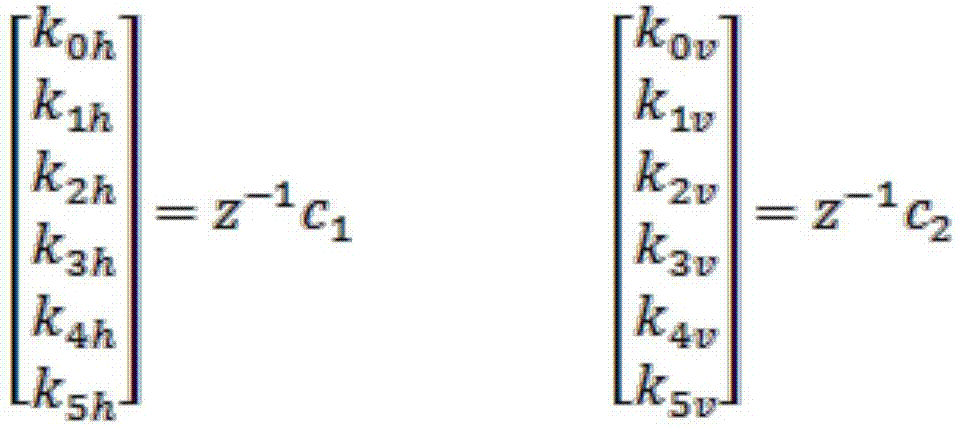

[0039] The present invention controls the change of the azimuth angle and the pitch angle of the reflector through the motor controller, and monitors it with the theodolite, thereby obtaining n×n points (x, y, h) and (x, y, v) respectively, and finally based on matlab, Use multiple surface fittings to fit points (x, y, h) and (x, y, v) respectively, and obtain the coefficients in the formula for calculating the azimuth angle h' and the elevation angle v', after substituting into the formula, For any point in the imaging area, the corresponding azimuth and elevation angles can be obtained according to the formula.

[0040] The device of the present invention is mainly composed of a two-dimensional autocollimator to be calibrated, a double-sided reflector (both sides are coated with a reflective film, hereinafter referred to as the reflector), a two-dimensional motor controller and a theodolite. The azimuth and elevation angles of the mirror are controlled by a two-dimensional m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com