Welding method of pre-embedded steel bar welded joints at the two ends of primary buckle arch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

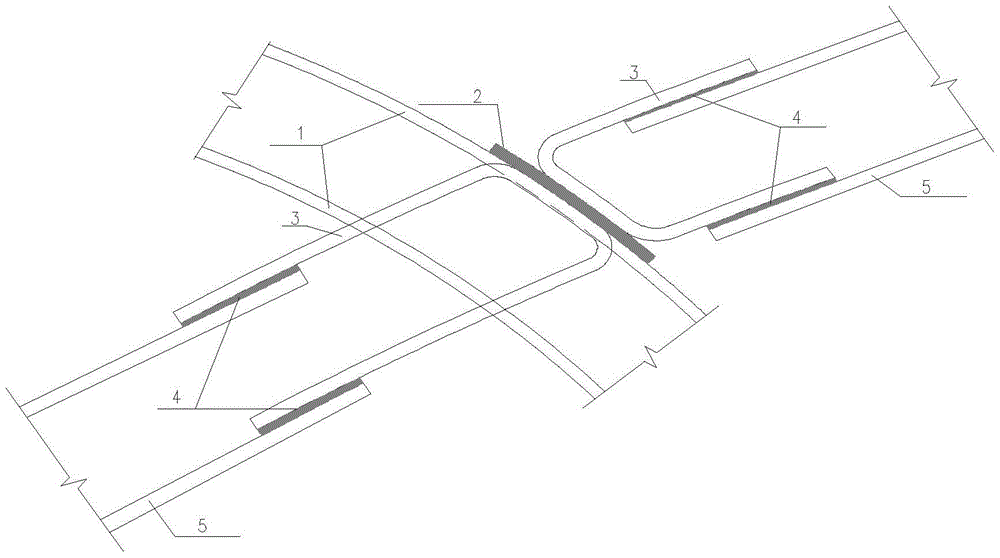

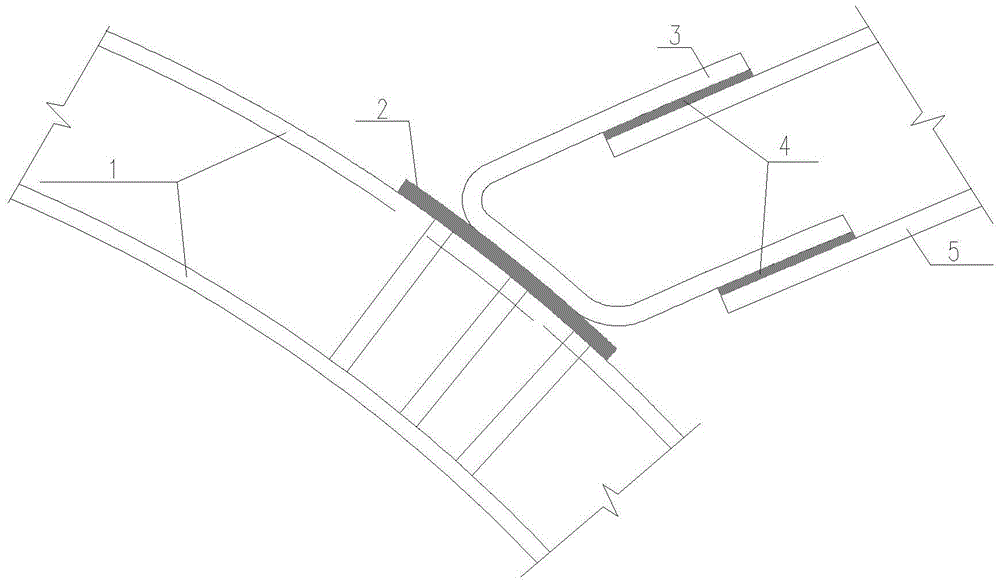

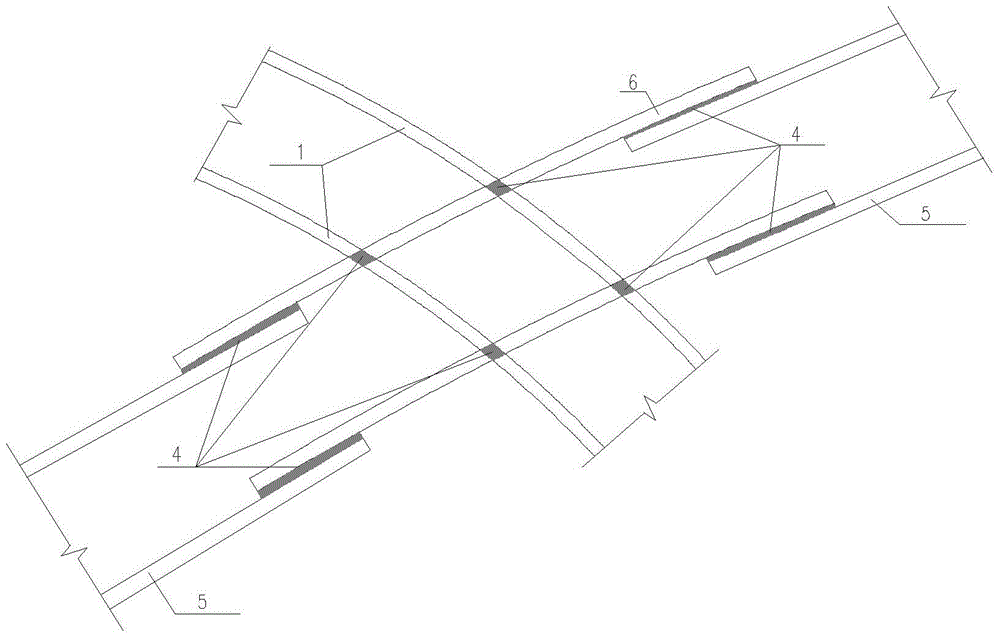

[0016] Such as image 3 , 4 Shown: a welding method for pre-embedded steel bar welding joints at the two ends of the primary buckle arch. When installing the side pilot hole grid, first determine the position and direction of the pre-embedded steel bar, and drill along the pre-embedded direction of the steel bar on the outer soil layer. Set up four soil holes, then insert the pre-embedded steel bar, adjust the direction of the steel bar, press image 3 Weld the intersection of the pre-embedded steel bar and the main bar of the pilot tunnel grid firmly, and ensure that the exposed length of the steel bar exceeds 10 times the diameter of the main bar; Four soil holes are drilled in the outer soil layer along the pre-embedded direction of the steel bar, according to Figure 4 Weld the U-shaped steel bar to the main bar of the pilot hole grid firmly, and ensure that the length of the exposed steel bar exceeds 10 times the diameter of the main bar.

[0017] The present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com