New application of glucoamylase, gas hydrate accelerator containing glucoamylase and method for preparing gas hydrate using the accelerator

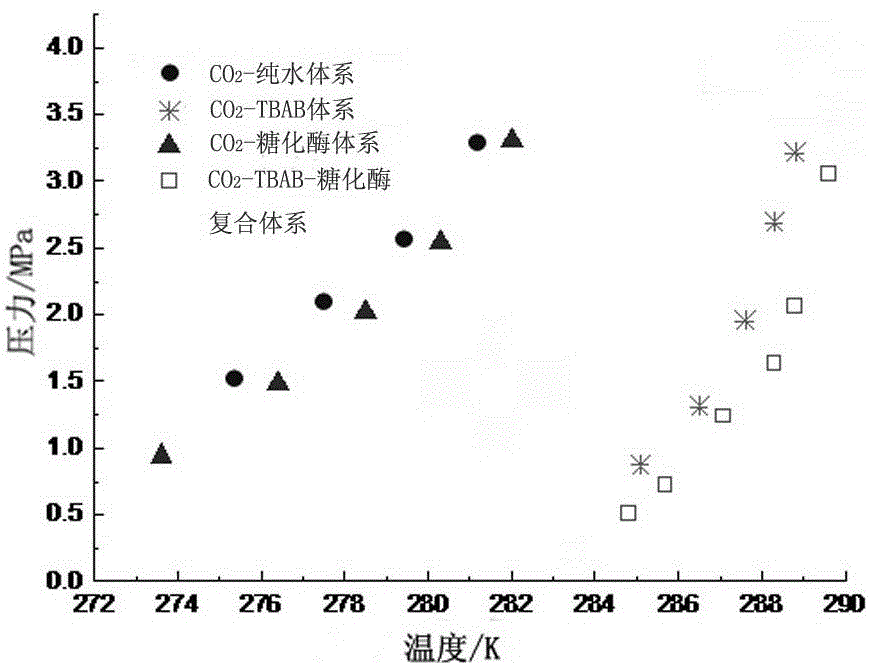

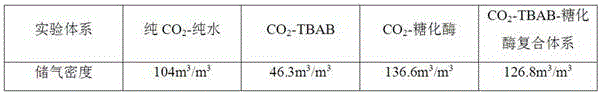

A gas hydrate and saccharifying enzyme technology, which is applied in the field of gas hydrate accelerator and the preparation of gas hydrate by using the accelerator, can solve the problem of large amount of chemical accelerator, lowering of hydrate phase equilibrium point, and lowering of hydrate gas storage density. and other problems, to achieve the effect of facilitating industrialization and application, improving economic applicability, and improving gas storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The saccharification enzyme is used to increase the storage density of gas hydrate.

[0031] Prepare glucoamylase and tetrabutylammonium bromide into a gas hydrate accelerator, wherein, tetrabutylammonium bromide is 10g, glucoamylase 8.0×10 6 u, the specification of glucoamylase raw material in this example is 5.5×10 6 u / g, the raw material of glucoamylase is 1.45g.

[0032] Using this accelerator to produce CO 2 A method of hydrating, comprising the steps of:

[0033] 1) Preparation of solution: Take tetrabutylammonium bromide, glucoamylase, and water to make a mixed solution, add 10g of tetrabutylammonium bromide, glucoamylase 8.0×10 per 100g of mixed solution 6 u;

[0034] 2) Pass CO into the mixed solution obtained in step 1) 2 The gas is hydrated at a pressure of 2.5MPa and a temperature of 284K to obtain a gas hydrate.

Embodiment 2

[0036] A gas hydrate accelerator, the active ingredients of which are tetrabutylammonium bromide and glucoamylase, wherein 5g of tetrabutylammonium bromide and glucoamylase take 7.4×10 6 u.

[0037] Using this accelerator to produce CO 2 A method of hydrating, comprising the steps of:

[0038] 1) Preparation solution: Take tetrabutylammonium bromide, glucoamylase, and water to make a mixed solution, add 5g of tetrabutylammonium bromide, glucoamylase 7.4×10 per 100g of mixed solution 6 u;

[0039] 2) Pass CO into the mixed solution obtained in step 1) 2 The gas is hydrated at a pressure of 0.5MPa and a temperature of 280K to obtain a gas hydrate.

Embodiment 3

[0041] A gas hydrate accelerator, the active ingredients of which are tetrabutylammonium bromide and glucoamylase, wherein 8g of tetrabutylammonium bromide and 8.5×10 glucoamylase 6 u.

[0042] Using this accelerator to produce CO 2 A method of hydrating, comprising the steps of:

[0043] 1) Preparation of solution: Take tetrabutylammonium bromide, glucoamylase, and water to make a mixed solution, add 8g of tetrabutylammonium bromide, 8.5×10 glucoamylase to each 100g of mixed solution 6 u;

[0044] 2) Pass CO into the mixed solution obtained in step 1) 2 The gas is hydrated at a pressure of 5.0MPa and a temperature of 288K to obtain a gas hydrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com