Automatic delivering platform of bagged feed

A platform and feed technology, applied in the direction of transportation and packaging, loading/unloading, conveyor objects, etc., can solve the problems of high labor intensity, long loading time, low work efficiency, etc., and achieve low labor intensity, high work efficiency, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

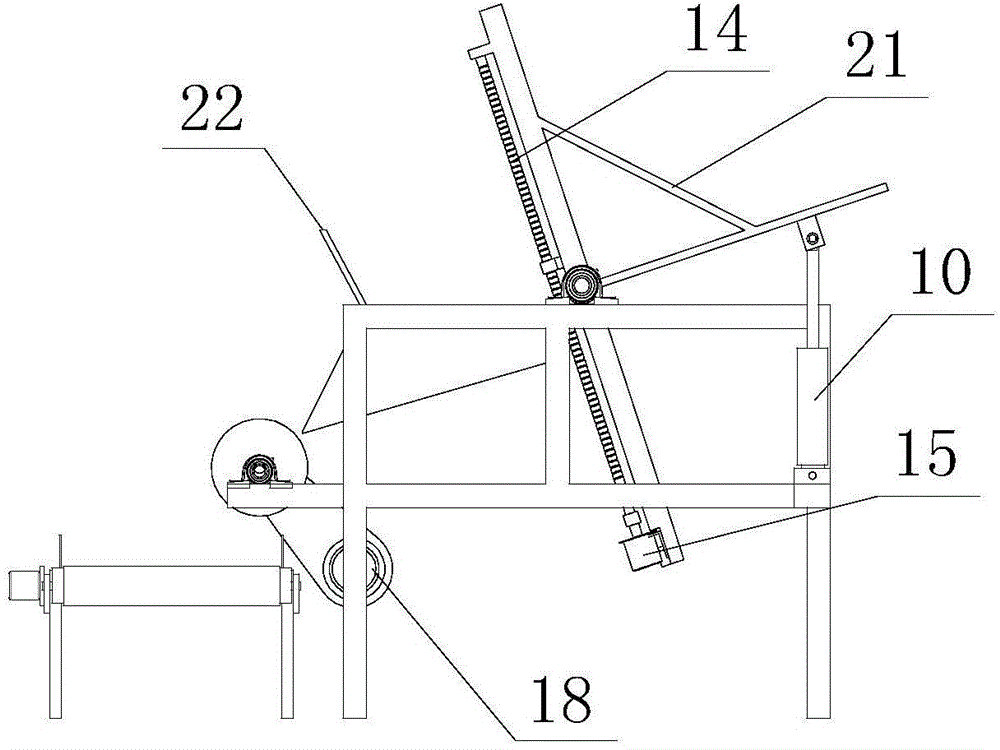

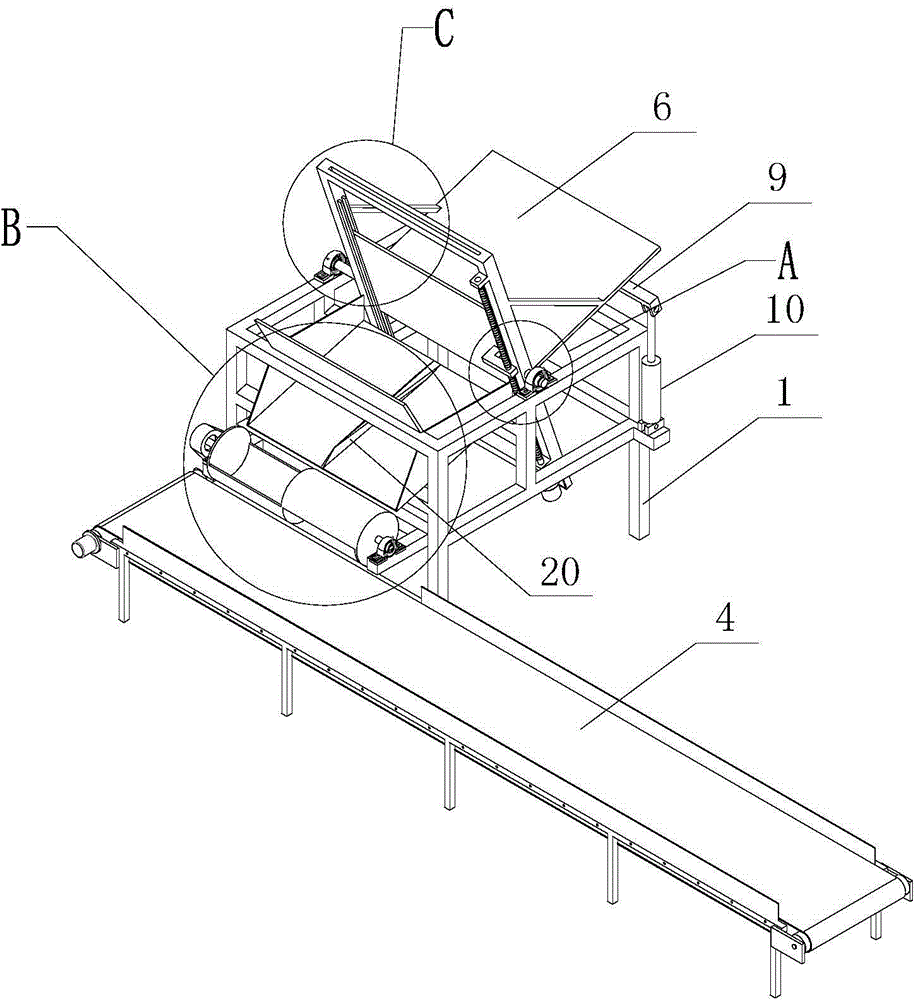

[0021] This embodiment provides an automatic delivery platform for bagged feed. The delivery platform includes a support 1 arranged horizontally. On the support 1, a rotating platform mechanism for placing bagged feed is provided. The mobile baffle 2 that moves up and down, one side of the mobile baffle 2 is also inclined to be provided with a transition platform 3, and the transition platform 3 is located at the lower end and is provided with a feed bag equalizing device that can discharge materials one by one. A delivery platform 4 is provided;

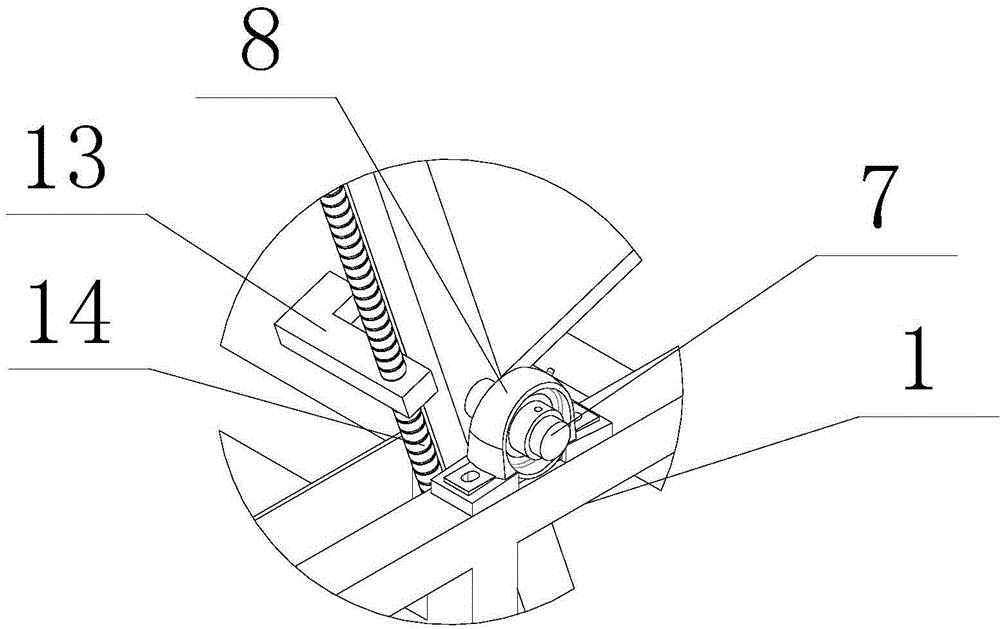

[0022] The rotating platform mechanism includes a rectangular rotating frame 5, the rotating frame 5 is located in the middle position and is provided with a placement platform 6 perpendicular to it, and a rotating shaft 7 is provided on both sides of the rotating frame 5 along its width direction, and the rotating shaft 7 passes through the sleeve The bearing seat 8 is connected to the bracket 1, the lower end of the placement pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com