Bucket elevator having high front edge opening

A bucket elevator and hoist technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of increasing production costs, waste of raw materials, and materials flowing out of the bucket, and achieve the effect of increasing the lifting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

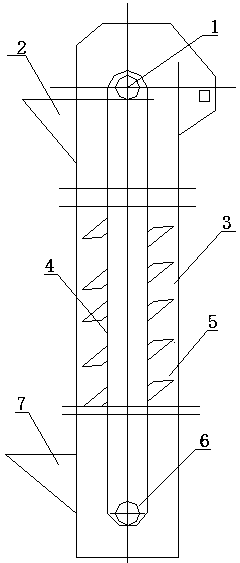

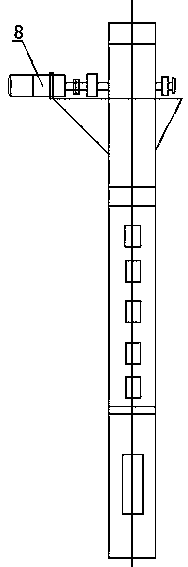

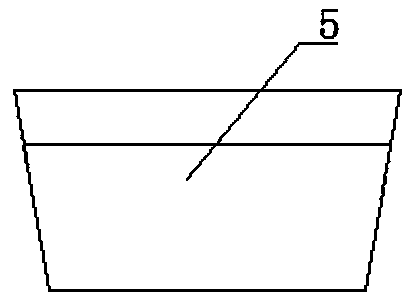

[0016] The invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as Figure 1-4 , the hoist of the present invention includes: a machine base, a machine head, a motor 8, a traction member 4, a housing 3, the machine base includes a feed port 2, a tensioning wheel 6, and the machine head includes a motor 8, a driving wheel 1 and an outlet The feed port 7 and the traction member 4 are placed in the housing 3, and the traction member 4 is fixedly connected with the pan 5, the front edge 9 of the pan is higher than the side wall 10 of the pan, the motor 8 is connected with the driving wheel 1 through a coupling, and the traction Part 4 is a belt drive or a chain drive, the drive wheel 1 and the tension wheel 6 work together, the drive wheel 1 and the tension wheel 6 are pulleys or sprockets, the feed port 2 and the discharge port 7 are made of angle steel or thin steel plate Formed, the tensioning wheel 6 or the driving wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com