A steam turbine clapboard drawing steel wire alignment device

A steam turbine and steel wire drawing technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inaccurate control of steel wire tensile stress, inaccurate vertical and horizontal positioning, and inability to effectively adjust the vertical arc of steel wire, etc. , to achieve the effects of easy on-site acquisition, convenient production, and effective control of the tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

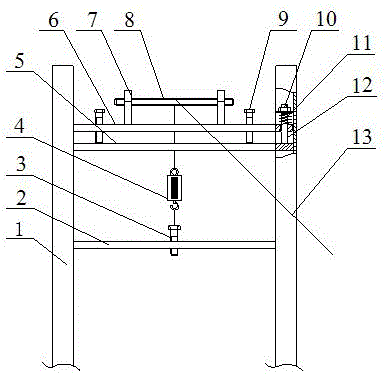

[0019] The utility model relates to a device for aligning steel wires for separating plates of steam turbines. Such as figure 1 As shown, the device includes two channel steels 1, a lower fixed beam 2, an upper fixed beam 5, a movable beam 6, a cylindrical guide rod 12, an adjusting screw 8, an adjusting bolt 9, a fastening bolt 3 and a spring dynamometer 4.

[0020] An upper fixed crossbeam 5 is horizontally fixed on the grooved inner walls of the two channel steels 1 , and cylindrical guide rods 12 are symmetrically fixed on the upper plane near the two ends of the upper fixed crossbeam 5 . Two ends near the movable crossbeam 6 are provided with round holes, and the movable crossbeam 6 is looped over the upper fixed crossbeam 5 through the round hole and the cylindrical guide rod 12 . A spring 11 is installed on the top of the cylindrical guide rod 12, and the spring 11 is located between the movable beam 6 and the nut 10.

[0021] Both sides of the middle position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com