3D printing chocolate nozzle

A 3D printing and chocolate technology, applied in the field of 3D printing chocolate nozzles, can solve problems such as designing 3D printing heads, and achieve the effect of improving extrusion quality, uniform and stable extrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

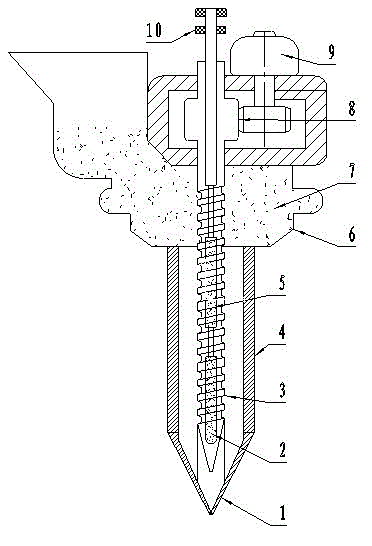

[0009] Below in conjunction with Fig. 1, describe in detail the concrete work situation that the present invention proposes, figure 1 middle

[0010] A screw feeding rod 3 is installed in the extrusion head 1, and the screw feeding rod 3 is divided into upper and lower sections, and an end heater 2 and a front heater 5 are installed, and a heater conductive ring 10 is fixed on the top of the screw feeding rod 3 , the screw feeding rod 3 is connected to the feeding motor 9 through the feeding rod transmission gear 8, a hopper 6 and a built-in chocolate particle 7 are installed between the middle part of the screw feeding rod 3 and the feeding rod transmission gear 8, and the outer packaging of the extrusion head 1 There is insulation layer 4.

[0011] By installing the terminal heater 2 and the front heater 5 in the screw feeding rod 3, a more uniform and stable extrusion effect can be achieved. The outer layer of the extrusion head 1 is equipped with an insulation layer 4, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com